Omron

Omron

CP1 Series

CP2M Series

CJ TCP FINS Ethemet

Supported device:CJ series, CJ1W-EIP21,CJ2M-EIP21

V-Box Settings

| Items | Settings |

|---|---|

| Protocol | OMRON CJ TCP FINS Ethemet |

| Connection | Ethernet |

| Port No. | 9600 |

| Device No. | 0 |

| V-Box No. | 0 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | CIO | CIO | CIO d | 0~99999 | |

| W | W | W d | 0~99999 | ||

| D | D | D d | 0~99999 | ||

| H | H | H d | 0~99999 | ||

| A | A | A d | 0~99999 | ||

| T | T | T h | 0~99999 | ||

| CF | CF | CF d | 0~99999 | ||

| FF | FF | FF d | 0~99999 | ||

| C | C | C d | 0~99999 | ||

| EM0 | EM0 | EM0 d | 0~99999 | ||

| EM1 | EM1 | EM1 d | 0~99999 | ||

| EM2 | EM2 | EM2 d | 0~99999 | ||

| EM3 | EM3 | EM3 d | 0~99999 | ||

| EM4 | EM4 | EM4 d | 0~99999 | ||

| EM5 | EM5 | EM5 h | 0~99999 | ||

| EM6 | EM6 | EM6 d | 0~99999 | ||

| EM7 | EM7 | EM7 d | 0~99999 | ||

| EM8 | EM8 | EM8 d | 0~99999 | ||

| EM9 | EM9 | EM9 d | 0~99999 | ||

| EMA | EMA | EMA d | 0~99999 | ||

| EMB | EMB | EMB d | 0~99999 | ||

| EMC | EMC | EMC d | 0~99999 | ||

| Lamp | Lamp | Lamp d | 0~0 | ||

| Word | CIO | CIO | CIO d | 0~99999 | |

| W | W | W d | 0~99999 | ||

| D | D | D d | 0~99999 | ||

| H | H | H d | 0~99999 | ||

| A | A | A d | 0~99999 | ||

| T | T | T h | 0~99999 | ||

| CF | CF | CF d | 0~99999 | ||

| FF | FF | FF d | 0~99999 | ||

| C | C | C d | 0~99999 | ||

| EM0 | EM0 | EM0 d | 0~99999 | ||

| EM1 | EM1 | EM1 d | 0~99999 | ||

| EM2 | EM2 | EM2 d | 0~99999 | ||

| EM3 | EM3 | EM3 d | 0~99999 | ||

| EM4 | EM4 | EM4 d | 0~99999 | ||

| EM5 | EM5 | EM5 h | 0~99999 | ||

| EM6 | EM6 | EM6 d | 0~99999 | ||

| EM7 | EM7 | EM7 d | 0~99999 | ||

| EM8 | EM8 | EM8 d | 0~99999 | ||

| EM9 | EM9 | EM9 d | 0~99999 | ||

| EMA | EMA | EMA d | 0~99999 | ||

| EMB | EMB | EMB d | 0~99999 | ||

| EMC | EMC | EMC d | 0~99999 | ||

| IR | IR | IR d | 0~99999 | ||

| DR | DR | DR d | 0~99999 |

PLC setting

①[PLC]→[Change Communication Settings]→[Network Type] Ethernet→[setting…]→[Derive]→[IPaddress]set the IP address as PLC’s ,192.168.40.99→[Port Number]9600→[OK]→[OK]

Note:The IP address of the PLC is displayed on the LED when the PLC is powered up

②[PLC]→[Work Online]→USB connection between PC and PLC→The connection prompt appears→[Yes]

③PLC default parameters: [IO Table and Unit Settings] → [Built-in Port/Inner Board] [1500] CJ2M-EIP21→[TCP/IP] → [Transfer [Unit to PC]] → Transfer successfully, click [Close]

[IP Address] Use the following address → [IP Address] 192.168.40.99, [Subnet Mask] 255.255.255.0.

Note: Please configure the IP parameters of PLC according to the field needs

④Two rotary coding switches should be set depanding on the program paremeter:

a) rotary coding switch for unit No. :For example, [Built-in Port/Inner Board] [1500] CJ2M-EIP21(Built In EtherNet/IP Port for CJ2M)(Unit: 0),the rotary coding switch should be dialed to 0

b) rotary coding switch for node No. :The high byte 4 of the IP address should be the same as theone configured by the software. such as [IP address] 192.168.40.99. The IP address high byte 4 is 99,rotary coding switch is to use hexadecimal 63 corresponds to decimal 99, node number dialling code 161 corresponds to: 6, 160 corresponds to: 3.Address List

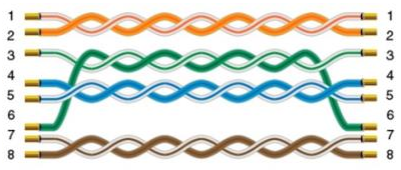

Cable Wiring

Pin Definition Diagram

EC55 Series

Supported device: EC55 temperature instrument

1)V-BOX Settings

| Items | Settings | Note |

| Protocol | Omron EC55 | |

| Connection | RS485 (9600, 2, 7, EVEN) | |

| Port No. | None | |

| PLC station No. | 0 |

2)Address List

| Type | Register | Device range | HMI range | Function |

| Double word | C0 | 0-13 (Hex) | 0-19 | Set read only parameter for area 0 |

| C1 | 0-4D(Hex) | 0-77 | Set Read/Write parameter for area 0 | |

| C3 | 0-CD(Hex) | 0-205 | Set Read/Write parameter for area 1 | |

| Word | 80 | 0-13(Hex) | 0-19 | Set read only parameter in area 0 |

| 81 | 0-4D(Hex) | 0-77 | Set Read/Write parameter in area 0 | |

| 83 | 0-CD(Hex) | 0-205 | Set Read/Write parameter in area 1 | |

| CP | - | 0-6 | Read controller intrinsic property | |

| CS | - | 0-2 | Read controller states | |

| CA | - | 0-17 | Action command |

3)Device Settings

Omron E5CC PLC configuration

After entering the Communication Settings menu, please set the parameters to the default values for the following table. Press the cycle key of the instrument to enter the next setting.

According to PLC configuration and communication port configuration information of the HMI, provide the corresponding steps and configuration screenshots. This configuration needs to communicate properly with the above PLC configuration. The project settings are as follows

✎Note: The communication settings for HMI should be consistent with this setting.

4)Configure the communication protocol

5)Cable Wiring

✎Note:

- COM3 only available in PI8000/PI9000 series.

- CA address could not support continuous writing function;

- Because of CP address intrinsic property: read control intrinsic property, so please place the character input part in use. Set address with CP0 and character length 10, used to display controller type. And place a number input part, set address with CP5 (cache size). Do not place other CP type address without CP0 in screen, otherwise CP type address is invalid

- When set value into read & write address, it is necessary to switch the temperature instrument meter to the corresponding interface according to the menu of the instrument where the address locates, so that the value could be written, otherwise, the value could not be written; When the communication write setting of the instrument is turned off, the writing function is invalid. Writing function could be opened by using the 00 address of the CA register, which write 01 value.

- When continuous writing of a value to a read-write address, please make sure all continuous writing address could be written. Otherwise, if one of these addresses could not be written, then all continuous writing commands will fail.

- Because of the mechanism problem, this protocol could not support CompoWay/F function that is read-write function of variables in protocol document.

- When using double-word address, set the data format to 32 bits, otherwise the read/write function is unable.

- Please set the communication delay time of 10ms in setting, to avoid that the instrument may not be able to communicate in a short time due to too fast data access and too much connection requests.

Because of the particularity of the instrument, it is necessary to write the value of the address in the menu interface corresponding to the address, and to enter the menu where the address locates, so that the value could be written.

Because of the particularity of the instrument, it is necessary to write the value of the address in the menu interface corresponding to the address, and to enter the menu where the address locates, so that the value could be written.