10 Malfunctions

Faults and warnings handling at startup

Position control mode

| Boot process | Fault phenomenon | Reason | Confirmation method |

|---|---|---|---|

Power supply (L1, L2, L3) Turn on control supply (L1C, L2C) |

| Control terminal is disconnected | ✎Rewiring ✎L1C and L2C power lines are led separately from the socket |

| Control the supply voltage failure | Measures the AC voltage between L1C &L2C. | ||

| Servo drive fault | Contact the agent or customer service | ||

| Panel display “Er.xx” | Refer to 10.2 Handling of faults and warnings during operation | ||

| After removing the fault, the servo drive panel should display "rdy" | |||

| Servo drive enable signal is valid(S-ON is ON) | The axis of servo motor is in a free running state | Servo enable signal is invalid | ✎Check whether group P06 is set the servo enable signal (DI function 1: S-ON). If it is, check whether the corresponding DI terminal logic is valid. If it is invalid,please make it valid. Refer to Group P06 DI/DO configuration ✎If group P06 parameters have set the servo enable signal, and the corresponding terminal logic is valid, but the panel still displays "rdy", check whether the DI terminal wiring is correct, please refer to 4 Wiring |

| Control mode error | Check whether the parameter P00-01 is set correctly | ||

| Panel display Er.xx | Refer to 10.2 Handling of faults and warnings during operation | ||

| After troubleshooting, the servo drive panel should display "run" | |||

| Input position instruction | The motor does not rotate | U0-09 (input instruction pulse number) always displays 0 | ✎Not input position instruction

|

| After troubleshooting, the servo motor should be able to rotate normally | |||

| The motor does not rotate smoothly at low speed | Unstable low speed | Unreasonable gain setting | Please adjust the gain. |

| The motor shaft vibrates left and right | Load inertia ratio is too large | After the inertia recognition is complete, performs gain adjustment. | |

| After troubleshooting, the servo motor should be able to rotate normally | |||

| Normal operation | Inaccurate positioning | There is a position deviation that does not meet production requirements | ✎Confirm the U0-09 value (input instruction pulse number) is consistent with the actual one sent by the host computer. If not, please check confirm whether the motor is blocked. ✎Confirm whether the device is vibrating. If yes, adjust the gain. ✎Confirm whether the coupling at the motor shaft is locked. |

Speed control mode

| Boot process | Fault phenomenon | Reason | Confirmation method |

|---|---|---|---|

Power supply (L1, L2, L3) Turn on control supply (L1C, L2C) |

| Control terminal is disconnected | ✎Rewiring ✎L1C and L2C power lines are led separately from the socket |

| Control the supply voltage failure | Measures the AC voltage between L1C &L2C. | ||

| Servo drive fault | Contact the agent or customer service | ||

| Panel display “Er.xx” | Refer to 10.2 Handling of faults and warnings during operation | ||

| After removing the fault, the servo drive panel should display "rdy" | |||

| Servo drive enable signal is valid(S-ON is ON) | The axis of servo motor is in a free running state | Servo enable signal is invalid | ✎Check whether group P06 is set the servo enable signal (DI function 1: S-ON). If it is, check whether the corresponding DI terminal logic is valid. If it is invalid,please make it valid. Refer to Group P06 DI/DO configuration ✎If group P06 parameters have set the servo enable signal, and the corresponding terminal logic is valid, but the panel still displays "rdy", check whether the DI terminal wiring is correct, please refer to 4 Wiring |

| Control mode error | Check whether the parameter P00-01 is set correctly | ||

| Panel display Er.xx | Refer to 10.2 Handling of faults and warnings during operation | ||

| After troubleshooting, the servo drive panel should display "run" | |||

| Input torque instruction | The motor does not rotate | U0-03 (input instruction pulse number) always displays 0 | ✎AI wiring error When selecting analog input signal, make sure that the connection of analog input terminal is correct. Refer to 4 Wiring. ✎Not input speed instruction or speed instruction abnormal

|

| After troubleshooting, the servo motor should be able to rotate normally | |||

| The motor does not rotate smoothly at low speed | Unstable low speed | Unreasonable gain setting | Please adjust the gain. |

| The motor shaft vibrates left and right | Load inertia ratio is too large | After the inertia recognition is complete, performs gain adjustment. | |

| After troubleshooting, the servo motor should be able to rotate normally | |||

✎Note: VD2F and VD2L do not support monitoring u0-21 and U0-22.

Torque control mode

| Boot process | Fault phenomenon | Reason | Confirmation method |

|---|---|---|---|

Power supply (L1, L2, L3) Turn on control supply (L1C, L2C) |

| Control terminal is disconnected | ✎Rewiring ✎L1C and L2C power lines are led separately from the socket |

| Control the supply voltage failure | Measures the AC voltage between L1C &L2C. | ||

| Servo drive fault | Contact the agent or customer service | ||

| Panel display “Er.xx” | Refer to 10.2 Handling of faults and warnings during operation | ||

| After removing the fault, the servo drive panel should display "rdy" | |||

| Servo drive enable signal is valid(S-ON is ON) | The axis of servo motor is in a free running state | Servo enable signal is invalid | ✎Check whether group P06 is set the servo enable signal (DI function 1: S-ON). If it is, check whether the corresponding DI terminal logic is valid. If it is invalid,please make it valid. Refer to Group P06 DI/DO configuration ✎If group P06 parameters have set the servo enable signal, and the corresponding terminal logic is valid, but the panel still displays "rdy", check whether the DI terminal wiring is correct, please refer to 4 Wiring |

| Control mode error | Check whether the parameter P00-01 is set correctly | ||

| Panel display Er.xx | Refer to 10.2 Handling of faults and warnings during operation | ||

| After troubleshooting, the servo drive panel should display "run" | |||

| Input speed instruction | The motor does not rotate | U0-03 (input instruction pulse number) always displays 0 | ✎AI wiring error When selecting analog input signal, make sure that the connection of analog input terminal is correct. Refer to 4 Wiring. ✎Not input torque instruction

|

| After troubleshooting, the servo motor should be able to rotate normally | |||

| The motor does not rotate smoothly at low speed | Unstable low speed | Unreasonable gain setting | Please adjust the gain. |

| The motor shaft vibrates left and right | Load inertia ratio is too large | After the inertia recognition is complete, performs gain adjustment. | |

| After troubleshooting, the servo motor should be able to rotate normally | |||

✎Note: VD2F and VD2L do not support monitoring u0-21 and U0-22.

Faults and warnings handling during operation

Overview

The faults and warnings of Wecon VD2 series servo drives are graded according to their severity, which can be divided into four grades: Category 1> Category 2> Category 3 > Category 4. Severity level: Category 1> Category 2> Category 3 > Category 4, the specific classifications are as follows:

- Category 1: faults cannot be cleared;

- Category 2: faults are clearable;

- Category 3: faults are clearable;

- Category 4: warnings are clearable.

Among them, "clearable" means that the panel stops the fault display state by giving a "clear signal". The specific operations are as follows:

- Set the function code P10-03=1 (fault clearing) or use DI function 02 (02-A-CLR, fault and warning clearing) and set it to logic valid, which can stop the fault display on the panel.

- The clearing method of category 2 and category 3 clearable faults: first turn off the servo enable signal (set S-ON to OFF), then set P10-03=1 or use DI function 02.

- The clearing method of category 4 of clearable warnings: set P10-03=1 or use DI function 02.

|

| For some faults and warnings, you must change the settings to eliminate the causes before they can be cleared, but clearing does not mean that the changes take effect. For the changes that need to be re-powered to take effect, the power must be re-powered. For the changes that need to be stopped to take effect, the servo enable must be turned off. After the change takes effect, the servo drive can operate normally. |

Associated function codes

| Function Code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P10-03 | Fault clearing | Operation setting | immediately Effective | 0 | 0 to 1 | 0: No operation 1: For clearable faults, after the cause of fault is removed, and write 1 to the function code, the drive will stop the fault display and enter the Rdy (or RUN) state again. ✎Note: If the servo S-ON is valid, when the fault is removed and cleared, the servo will directly enter the Run state. When performing fault clearing actions, be sure to stop sending control instructions such as pulses to ensure personal safety. | - |

Associated function number:

| Code | Name | Function name | Function |

| 2 | A-CLR | Fault and warning clearing | DI port logic is invalid, no reset faults and warnings DI port logic is valid, reset faults and warnings |

VD2 series servo drives have a fault recording function, which could record the last 5 faults and the last 5 warning names and the status parameters of servo drive when the fault or warning occurs. After the fault or warning is cleared, the fault record will still save the fault and warning.

The current fault code could be viewed through the monitoring parameter U1-01, and the current warning code could be viewed through U1-02. The monitoring U1-16 to U1-25 could display the last 5 fault codes and warning codes. Please refer to Group U1 Warning monitoring.

Fault and warning code table

The first category (category 1 for short) The fault could not be cleared

| Category | Error name | Fault code | Content | Whether Clearable | Operation |

|---|---|---|---|---|---|

| Category 1 | Parameter destruction | Er.01 | Abnormal servo internal parameters | No | Stop immediately |

| Category 1 | Parameter storage error | Er.02 | Abnormal servo internal parameters | No | Stop immediately |

| Category 1 | ADC reference source faults | Er.03 | Abnormal ADC reference source | No | Stop immediately |

| Category 1 | AD current sampling conversion error | Er.04 | AD current sampling conversion error | No | Stop immediately |

| Category 1 | Abnormal FPGA communication | Er.05 | Abnormal FPGA communication | No | Stop immediately |

| Category 1 | Wrong FPGA program version | Er.06 | Wrong FPGA program version | No | Stop immediately |

| Category 1 | Clock abnormal | Er.07 | Clock abnormal | No | Stop immediately |

| Category 1 | ADC conversion undone | Er.60 | ADC conversion error | No | Stop immediately |

| Category 1 | Internal software fault | Er.61 | Abnormal servo internal software | No | Stop immediately |

| Category 1 | Internal software fault | Er.62 | Abnormal servo internal software | No | Stop immediately |

| Category 1 | Internal software fault | Er.63 | Abnormal servo internal software | No | Stop immediately |

| Category 1 | Internal software fault | Er.64 | Abnormal servo internal software | No | Stop immediately |

| Category 1 | Internal software fault | Er.65 | Abnormal servo internal software | No | Stop immediately |

| Category 1 | Motor model error | Er.26 | Motor model error | No | Stop immediately |

| Category 1 | Encoder disconnection | Er.27 | The encoder cable is incorrectly connected | No | Stop immediately |

| Category 1 | Encoder Z pulse lost | Er.28 | Encoder Z pulse lost | No | Stop immediately |

| Category 1 | Encoder UVW signal error | Er.30 | Encoder UVW signal error | No | Stop immediately |

| Category 1 | Exceeds motor maximum speed | Er.32 | Exceeds motor maximum speed | No | Stop immediately |

| Category 1 | Over current | Er.20 | Servo drive hardware overcurrent | No | Stop immediately |

| Category 1 | The brake resistor is turned on abnormally | Er.24 | The brake resistor of servo drive is turned on abnormally | No | Stop immediately |

| Category 1 | Motor model error | Er.26 | Wrong servo motor model | No | Stop immediately |

| Category 1 | Encoder disconnection | Er.27 | Encoder cable wiring errors | No | Stop immediately |

| Category 1 | Encoder Z-pulse loss | Er.28 | Encoder Z-pulse loss | No | Stop immediately |

| Category 1 | Encoder UVW signal error | Er.30 | Encoder UVW signal error | No | Stop immediately |

| Category 1 | Exceeding the maximum speed of the motor | Er.32 | Motor speed exceeding the maximum speed limit | No | Stop immediately |

| Category 1 | ADC conversion not completed | Er.60 | The ADC conversion is abnormal | No | Stop immediately |

| Category 1 | Internal software fault | Er.61 | Abnormality occurred in the internal program of the servo unit | No | Stop immediately |

| Category 1 | Internal software fault | Er.62 | Abnormality occurred in the internal program of the servo unit | No | Stop immediately |

| Category 1 | Internal software fault | Er.63 | Abnormality occurred in the internal program of the servo unit | No | Stop immediately |

| Category 1 | Internal software fault | Er.64 | Abnormality occurred in the internal program of the servo unit | No | Stop immediately |

| Category 1 | Internal software fault | Er.65 | Abnormality occurred in the internal program of the servo unit | No | Stop immediately |

The 2nd category (category 2 for short) clearable faults

| Category | Error name | Fault code | Content | Whether Clearable | Operation |

|---|---|---|---|---|---|

| Category 2 | Main power supply overvoltage | Er.22 | Main power supply overvoltage | Yes | Stop immediately |

| Category 2 | Power line disconnection | Er.31 | The power cable is incorrectly connected | Yes | Stop immediately |

The 3rd Category (category 3 for short) clearable faults

| Category | Error name | Fault code | Content | Whether Clearable | Operation |

|---|---|---|---|---|---|

| Category 3 | Main power supply under voltage | Er.21 | Main power supply under voltage | Yes | Stop immediately |

| Category 3 | Braking resistor is not connected | Er.23 | Braking resistor is not connected | Yes | Stop immediately |

| Category 3 | Braking resistor resistance is too large | Er.25 | Braking resistor resistance is too large | Yes | Stop immediately |

| Category 3 | Power module is over temperature | Er.33 | Power module is over temperature | Yes | Stop immediately |

| Category 3 | Motor overload protection | Er.34 | Motor overload protection | Yes | Stop immediately |

| Category 3 | Electronic gear ratio exceeds limit | Er.35 | Electronic gear ratio exceeds limit | Yes | Stop immediately |

| Category 3 | Position deviation is too large | Er.36 | Position deviation is too large | Yes | Stop immediately |

| Category 3 | Torque saturation abnormal | Er.37 | Torque saturation abnormal | Yes | Stop immediately |

| Category 3 | Main circuit electricity is lack of phase | Er.38 | Main circuit electricity is lack of phase | Yes | Stop immediately |

| Category 3 | Emergency stop | Er.39 | Triggered the emergency stop signal | Yes | Stop immediately |

| Category 3 | Encoder battery failure | Er.40 | Encoder battery failure | Yes | Stop immediately |

| Category 3 | Motor (encoder) over temperature | Er.41 | Motor (encoder) over temperature | Yes | Stop immediately |

| Category 3 | Encoder write faults | Er.42 | The encoder fails to write data | Yes | Stop immediately |

| Category 3 | Drive overload alarm | Er.43 | The drive exceeds the power limit for more than 20 minutes | Yes | Stop immediately |

| Category 3 | Drive stall over temperature alarm | Er.45 | The drive controls the motor and it is stalled | Yes | Stop immediately |

The 4th category (category 4 for short) clearable warnings

| Category | Error name | Fault code | Content | Whether Clearable | Operation |

|---|---|---|---|---|---|

| Category 4 | Drive over-power alarm | A-80 | The driver exceeds the power limit for more than 5 seconds | Yes | Continue to run |

| Category 4 | Overspeed alarm | A-81 | Motor exceeds the speed limit | Yes | Continue to run |

| Category 4 | Overload | A-82 | The motor was run continuously with a torque exceeding the rated value | Yes | Continue to run |

| Category 4 | Braking resistor is over temperature or overloaded | A-83 | Braking resistor is over temperature or overloaded | Yes | Continue to run |

| Category 4 | Parameter modification that needs to be powered on again | A-84 | Modify the parameter that needs to be powered on again | Yes | Continue to run |

| Category 4 | Receive position pulse when servo is OFF | A-85 | Servo drive receives position pulse when it is OFF | Yes | Continue to run |

| Category 4 | Input pulse frequency is too high | A-86 | Input pulse frequency is too high | Yes | Continue to run |

| Category 4 | Main circuit momentary power off | A-88 | Main circuit momentary power off | Yes | Continue to run |

| Category 4 | DI port configuration is duplicate | A-89 | DI port configuration is duplicate | Yes | Continue to run |

| Category 4 | DO port configuration is duplicate | A-90 | DO port configuration is duplicate | Yes | Continue to run |

| Category 4 | Parameter modification is too frequent | A-91 | Parameter modification is too frequent | Yes | Continue to run |

| Category 4 | low encoder battery voltage Warning | A-92 | The battery voltage of encoder is less than 3.1V | Yes | Continue to run |

| Category 4 | Encoder read and write check abnormal and frequency is too high | A-93 | Encoder read and write check abnormal and frequency is too high | Yes | Continue to run |

Troubleshooting

Er.01 Parameter destruction

Fault

| Servo drive panel display | Fault name |

|---|---|

| Parameter destruction |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| EEPROM could not be read and written | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | Please contact the technician. |

Er.02 Parameter storage error

Fault

| Servo drive panel display | Fault name |

|---|---|

| Parameter storage error |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Firmware upgraded | Check whether the program has been upgraded. | Power on the servo drive again |

| Parameter read and write exceptions | After a parameter is changed, power it on again and check whether the parameter is saved | If the parameters are not saved after multiple power-on, contact technician. |

| Servo drive firmware faulty | Check if the servo drive monitoring quantity U2-04 (firmware version) is in the following range. VD2-0xxSA1G model: earlier than V1.14. VD2F-0xxSA1P model: earlier than V1.02 | VD2-0xxSA1G model: Contact manufacturer to upgrade the firmware to V1.14 and above. VD2F-0xxSA1P model: Contact technician to upgrade the firmware to V1.02 and above. |

Er.03 ADC reference source fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| ADC reference source fault |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The internal analog reference source of the drive is not accurate | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.04 AD current sampling conversion error

Fault

| Servo drive panel display | Fault name |

|---|---|

| AD current sampling conversion error |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Current sampling timeout | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

| current sensor error |

Er.05 FPGA communication abnormal

Fault

| Servo drive panel display | Fault name |

|---|---|

| FPGA communication abnormal |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| FPGA communication abnormal | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.06 Wrong FPGA program version

Fault

| Servo drive panel display | Fault name |

|---|---|

| Wrong FPGA program version |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The FPGA program version does not match firmware version | Check whether the monitoring quantity of servo drive U2-04 (firmware version) and U2-05 (hardware version) conform to the following table | Contact technical to upgrade FPGA (hardware version) |

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

| Firmware version | Hardware version |

|---|---|

| 1.00 | 1.00 |

| 1.10 | 1.01 |

| 1.11 | 1.01 |

| 1.12 | 1.01 |

| 1.13 | 1.01 |

| 1.14 | 1.01 |

Table 10-1 The firmware version and hardware version relationship of VD2-0SA1G servo drive

Er.07 Clock abnormal

Fault

| Servo drive panel display | Fault name |

|---|---|

| Clock abnormal |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| External interference | Check for strong magnetic fields nearby | Eliminate nearby strong magnetic interference |

| Check whether there are sources of interference such as power supply inverter equipment nearby | Separate strong and weak power as much as possible, with good ground contact between motor and servo drive, and keep away from power cable wiring. | |

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

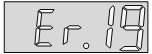

Er.19 Overcurrent

Fault

| Servo drive panel display | Fault name |

| Software overcurrent |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

| The UVW phase sequence of motor power cable is incorrect | Check whether the phase sequence of the motor power cable on the servo drive side and motor side corresponds to each other. | Connect correctly according to UVW on the drive side and UVW on the motor side |

| Motor power cables are short-circuited | Check whether power cable UVW is short-circuited to PE | Replace motor power cable |

| The motor power cable wiring port is poorly contacted | Check whether the motor power cable connection port is connected reliably | Tighten the fixing screws of the motor power cable connection ports |

| Abnormal braking resistance | Internal brake resistance wiring error: check whether C, D are connected to the short cap and the contact is normal | Connect the short cap or short wire between C and D reliably |

| External braking resistor wiring error: Check whether the external resistor is connected reliably between P+ and C. | External braking resistance is reliably strung between P+ and C | |

| Short-circuit of the built-in brake resistance: Check whether the built-in brake resistance is short-circuited. | Remove the shorting cap between C and D, and reliably string the external braking resistor of equal resistance between P+ and C. Contact technician to replace the internal braking resistor | |

| The resistance value of the external braking resistor is too small: Test the resistance value of the external braking resistor actually selected and compare it with the recommended braking resistor to confirm whether the resistance value of the actual resistor is too small | Choose a suitable external braking resistor | |

| Encoder wiring error; loose plug | Check whether the cable port (CN1) of the encoder is properly connected | Tighten the fixing screws on the CN1 port |

| Check whether the servo drive CN1 port jack is deformed | If the cable is deformed, replace the cable or its port | |

| Check whether both ends of the rectangular connector are reliably connected | Make sure that both ends of the rectangular connector are connected reliably; Replace it with an encoder cable with higher connection reliability. | |

| Unreasonable parameter settings | Check that the 2003-01 load inertia ratio and 2003-02 (load rigidity class) settings are reasonable. | Set 2003-01 (load inertia ratio) to a reasonable value and appropriately adjusted 2003-02 (Load Rigidity Level) setting value. |

| Check whether the gain parameters are set properly, resulting in overshoot | Adjust gain parameters reasonably | |

| Frequent acceleration and deceleration | Check whether the acceleration and deceleration motion is frequent or the acceleration and deceleration time is too small | Appropriately extend the acceleration and deceleration time |

| Internal servo drive fault | Cross-verification. Use the normal motor, encoder cable to connect to the servo drive, only connect the encoder cable. If the servo drive still alarm, it is failure. | Contact technician for repair |

Er.20 Overcurrent

Fault

| Servo drive panel display | Fault name |

|---|---|

| Overcurrent |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The UVW phase sequence of motor power cable is incorrect | Check whether the phase sequence of the motor power cable on the servo drive side and motor side corresponds to each other. | Connect correctly according to UVW on the drive side and UVW on the motor side |

| Motor power lines are short-circuited | Check whether power line UVW is short-circuited to PE | Replace motor power line |

| The motor power line wiring port is poorly contacted | Check whether the motor power line connection port is connected reliably | Tighten the fixing screws of the motor power line connection ports |

| Abnormal braking resistance | Internal brake resistance wiring error: check whether C, D are connected to the short cap and the contact is normal | Connect the short cap or short wire between C and D reliably |

| External braking resistor wiring error: Check whether the external resistor is connected reliably between P+ and C. | External braking resistance is reliably strung between P+ and C | |

| Short-circuit of the built-in brake resistance: Check whether the built-in brake resistance is short-circuit. | Remove the shorting cap between C and D, and reliably string the external braking resistor of equal resistance between P+ and C. Contact technician to replace the internal braking resistor | |

| The resistance value of the external braking resistor is too small: Test the resistance value of the external braking resistor actually selected and compare it with the recommended braking resistor to confirm whether the resistance value of the actual resistor is too small | Choose a suitable external braking resistor | |

| Encoder wiring error; loose plug | Check whether the cable port (CN1) of the encoder is properly connected | Tighten the fixing screws on the CN1 port |

| Check whether the servo drive CN1 port jack is deformed | If the cable is deformed, replace the cable or its port | |

| Check whether both ends of the rectangular connector are reliably connected | Make sure that both ends of the rectangular connector are connected reliably; Replace it with an encoder cable with higher connection reliability. | |

| Unreasonable parameter settings | Check whether P03-02 (Load rigidity Level) is set properly | Reduce the P03-02 (load stiffness level) setting value appropriately |

| Check whether the gain parameters are set properly, resulting in overshoot | Adjust gain parameters reasonably | |

| Frequent acceleration and deceleration | Check whether the acceleration and deceleration motion is frequent or the acceleration and deceleration time is too small | Appropriately extend the acceleration and deceleration time |

| Internal servo drive fault | Cross-verification. Use the normal motor, encoder cable to connect to the servo drive, only connect the encoder cable. If the servo drive still alarm, it is failure. | Contact technician for repair |

Er.21 Main power supply undervoltage

Fault

| Servo drive panel display | Fault name |

|---|---|

| Main power supply undervoltage |

Reason: DC bus voltage is lower than the fault value.

- 220V drive: DC bus voltage normal value is 310V; DC bus voltage fault value is 200V.

- 380V drive: DC bus voltage normal value is 540V; DC bus voltage fault value is 420V.

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Power-off when VD2A drive is enabled | Check whether the servo drive is Power off when logic is valid.and the S-ON function is enabled in the P06 “DIDO Function configuration parameter”. | It belongs to servo internal software logic. When the indicator light on the servo drive panel goes out automatically, the alarm will be removed automatically. |

| The power supply is unstable or OFF. | Check whether the drive input power specifications meet the following specifications: 220V drive: Valid value is 198V to 242V. 380V drive: Valid value is 342V to 440V. | Use after the power supply is stable; Increase power supply capacity |

| The voltage drops during operation of the servo drive | Check whether the servo drive shares the same power supply with other high loads | Turn off other loads from the same main circuit power supply. Separate power supply for servo drives |

| Missing phase (3-phase power supply operating on single-phase power) | Check if the main circuit wiring is correct VD2A: single-phase 220V input connected to L1, L3. VD2 B: single-phase 220V input connected to L1, L3, and single-phase 220V input connected to L1C, L2C. VD2 B: three-phase 220V input connected to L1, L2, L3. VD2F: single-phase 220V input connected to L1, L2 | Connect the main circuit wiring correctly |

| Internal servo drive fault | Observe whether the monitoring quantity U0-31 (bus voltage) is in the following range: 220V drive: U0-31 less than 200V; 380V drive: U0-31 less than 400V. | Contact technician for repair |

Er.22 Main power supply overvoltage

Fault

| Servo drive panel display | Fault name |

|---|---|

| Main power supply overvoltage |

Reason: DC bus voltage is bigger than the fault value.

- 220V drive: DC bus voltage normal value is 310V; DC bus voltage fault value is 390V.

- 380V drive: DC bus voltage normal value is 540V; DC bus voltage fault value is 670V.

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The input voltage is too high | Check whether the drive input power specifications meet the following specifications: 220V drive: Valid value is 198V to 242V. 380V drive: Valid value is 342V to 440V. | Replace or adjust power supply |

| The power supply is not stable or struck by lightning | Check whether the input power supply of the servo drive meets the specifications and monitor whether it has been struck by lightning. | used after the power supply is stable Connect to surge suppressor |

| Abnormal braking resistance | Internal brake resistance wiring error: check whether C, D are connected to the short cap and the contact is normal | Connect the short cap or short wire between C and D reliably |

| External braking resistor wiring error: Check whether the external resistor is connected reliably between P+ and C. | External braking resistance is reliably strung between P+ and C | |

| Short-circuit of the built-in brake resistance: Check whether the built-in brake resistance is short-circuit. | Remove the shorting cap between C and D, and reliably string the external braking resistor of equal resistance between P+ and C. Contact technician to replace the internal braking resistor | |

| The resistance value of the external braking resistor is too large: Check the resistance value of the external braking resistor actually selected and compare it with the recommended braking resistor to confirm whether the resistance value of the actual resistor is too large. | Choose a suitable external braking resistor | |

| The motor is in a state of rapid acceleration and deceleration motion | Monitor the servo drive monitoring quantity U0-31 (bus voltage) to confirm whether the voltage exceeds the fault value when the motor is in the deceleration section. | Ensure that the input voltage is within specification and increase acceleration and deceleration times |

| Internal servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged and contact technician for repair |

Er.23 Braking resistor is not connected

Fault

| Servo drive panel display | Fault name |

|---|---|

| Braking resistor is not connected |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Internal brake resistance wiring error | Check whether C, D are connected to the short cap and the contact is normal | When using an internal braking resistor, reliably connect the shorting cap or shorting wire between C and D |

| External braking resistor wiring error | Check whether the external resistor is connected reliably between P+ and C. | When using an external braking resistor, the external resistor is reliably strung between P+ and C |

| Internal braking resistor damaged | The servo drive is powered off. Detects whether the resistance between P+ and D is 50Ω | Contact the technician to replace the internal braking resistor. Use an external braking resistor and change the relevant parameters of the P00 "Basic Settings". |

Er.24 Braking resistor turns on abnormally

Fault

| Servo drive panel display | Fault name |

|---|---|

| Braking resistor turns on abnormally |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Internal servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged.Contact technician for repair |

Er.25 Braking resistor resistance is too large

Fault

| Servo drive panel display | Fault name |

|---|---|

| Braking resistor resistance is too large |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The resistance value of the external braking resistor is too large | Check the resistance value of the external braking resistor actually selected and compare it with the recommended braking resistor to confirm whether the resistance value of the actual resistor is too large. | Choose a suitable external braking resistor |

| Unreasonable parameter settings | Check whether the value of servo drive P00-10 (external brake resistance) is set too high | Reasonably set the P00-10 (external braking resistor resistance) parameter value |

| Servo drive firmware fault | Check if the servo drive monitoring quantity U2-04 (firmware version) is in the following range. VD2-0xxSA1G model: earlier than V1.14. VD2F-0xxSA1P model: earlier than V1.01 | VD2-0xxSA1G model: Contact manufacturer to upgrade the firmware to V1.14 and above. VD2F-0xxSA1P model: Contact technician to upgrade the firmware to V1.02 and above. |

Er.26 Motor model error

Fault

| Servo drive panel display | Fault name |

|---|---|

| Motor model error |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drives do not support this motor | Check whether the servo driver model supports the motor | Contact technical for suitable recommendations of servo drive model or motor model. |

| Wrong motor model | Check whether the Motor Code is consistent with the Motor nameplate | Contact technician to record the motor Motor Code |

Er.27 Encoder disconnection

Fault

| Servo drive panel display | Fault name |

|---|---|

| Encoder disconnection |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Poor contact on CN1 port | Check whether the cable port (CN1) of the encoder is properly connected | Tighten the fixing screws on the CN1 port |

| Check whether the servo drive CN1 port jack is deformed | If the cable is deformed, replace the cable or its port | |

| Poor contact on adapter port (Rectangular connection cable) | Check whether both ends of the rectangular connector are reliably connected | Make sure that both ends of the rectangular connector are connected reliably; Replace it with an encoder cable with higher connection reliability. |

| Wrong encoder cable wiring | Check whether the both ends of the encoder cable are correctly connected | Adjust wiring according to the corresponding relationship of pins; The standard encoder cable of the manufacturer is preferred. |

Er.28 Encoder Z pulse lost

Fault

| Servo drive panel display | Fault name |

|---|---|

| Encoder Z pulse lost |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Wrong motor model | Check whether the Motor Code is consistent with the Motor nameplate | Contact technician to record the motor Motor Code |

| External interference | Check for strong magnetic fields nearby | Eliminate nearby strong magnetic interference |

| Check whether there are sources of interference such as power supply inverter equipment nearby | Separate strong and weak power as much as possible, with good ground contact between motor and servo drive, and keep away from power cable wiring. | |

| Encoder fault | Manually rotate the motor shaft counterclockwise or clockwise to observe whether the monitoring quantity U0-30 (electrical angle) changes regularly | If the value of U0-30 (electrical angle) changes abruptly or does not change, the encoder itself may have problems, please replace the motor or encoder. |

Er.30 Encoder UVW signal error

Fault

| Servo drive panel display | Fault name |

|---|---|

| Encoder UVW signal error |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| External interference | Check that the motor and servo drive are well grounded | Motor and servo drive are well grounded |

| Encoder cable fault | Cross-verification. Use the normal motor, encoder cable to connect to the servo drive. | Replace it with an encoder cable with higher connection reliability. |

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged. Contact technician for repair |

Er.31 Power line disconnection

Fault

| Servo drive panel display | Fault name |

|---|---|

| Power line disconnection |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The motor power line wiring port is poorly contacted | Check whether the motor power line connection port is connected reliably | Tighten the fixing screws of the motor power line connection ports |

| The power cable is disconnected | Check the power cable for disconnections at both ends | Replace the power cable and power on again. |

| Poor contact on adapter port (Rectangular connection cable) | Check whether both ends of the rectangular connector are reliably connected | Make sure that both ends of the rectangular connector are connected reliably; Replace it with an encoder cable with higher connection reliability. |

Er.32 Exceeds motor maximum speed

Fault

| Servo drive panel display | Fault name |

|---|---|

| Exceeds motor maximum speed |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The UVW phase sequence of motor power cable is incorrect | Check whether the phase sequence of the motor power cable on the servo driver side and motor side corresponds to each other. | Connect correctly according to UVW on the drive side and UVW on the motor side |

| P01-10 parameter Settings are incorrect | Check that the parameter value of P01-10 (maximum speed threshold) is less than the maximum speed required for the actual operation of the motor | Reset P01-10 (maximum speed threshold) according to mechanical requirements |

Check whether the motor speed corresponding to the input instruction exceeds P01-10 (maximum speed threshold). Position mode, when the instruction is from a pulse instruction (P01-06 = 0). Motor speed (rpm) = input pulse frequency (Hz) * 60 * electronic gear ratio / encoder resolution | ||

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged. Please replace the servo drive. |

Er.33 Power module is over temperature

Fault

| Servo drive panel display | Fault name |

|---|---|

| Power module is over temperature |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Ambient temperature is too high | Measure the ambient temperature | Reduce the ambient temperature of the servo drive |

| The cooling fan is faulty | Check the servo drive fan for blockage or damage | Contact technician for fan repair or replacement |

| The servo drive is mounted in an unreasonable orientation or the spacing between the servo drives is unreasonable | Check whether the servo drive installation is reasonable | Contact technical to obtain the installation standard of the servo drive |

| Servo drive fault | Restarting after 10 minutes of power failure is still reported | Servo drive may be damaged. Please replace the servo drive. |

Er.34 Motor overload protection

Fault

| Servo drive panel display | Fault name |

|---|---|

| Motor overload protection |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Motor power cable, encoder cable wiring error | Check whether the motor power cable and encoder cable wiring are correct. | Connect them according to the correct connection method. Priority is given to the use of motor power lines and encoder cables as standard by manufacturers |

| The load is too large | Check overload characteristics of motor or servo drive | Reduce the load. Contact technical to obtain the appropriate capacity drive and motor model. |

| Frequent acceleration and deceleration | Check whether the acceleration and deceleration motion is frequent or the acceleration and deceleration time is too small | Appropriately extend the acceleration and deceleration time |

| Motor model and servo driver do not match | Check the monitoring quantity U0-53 (motor model code). | Contact technician to obtain the matching motor model. |

| Unreasonable parameters | Use Wecon SCTools to obtain the actual torque waveform and observe whether overshoot is obvious | Set the appropriate loop gain parameters |

| Observe whether the motor vibrates during operation | Set the appropriate rigidity level | |

| Check whether p10-04 (Motor overload protection time coefficient) is reasonable | Increase P10-04 (motor overload protection time factor) in the case of ensuring that the motor will not burn out. | |

| Motor blockage | Check if the motor is blocked due to mechanical jamming of the load. | Release the mechanical jam. |

| The brakes are not open | Check whether the brake device is opened normally, and check whether the output voltage of the brake is 24V | Check the logic of brake power supply or brake output signal |

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged, please contact technician for repair. |

Er.35 Electronic gear ratio exceeds limit

Fault

| Servo drive panel display | Fault name |

|---|---|

| Electronic gear ratio exceeds limit |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The electronic gear ratio setting is greater than the settable range | Check that the ratio of function codes P00-17/P00-18, P00-19/P00-20 is in the following range. 17bit absolute encoder upper limit value: 500. 23bit absolute encoder upper limit value: 32000 | After modifying the corresponding function code according to the range, set P10-03 (fault clearance) to 1. |

| The electronic gear ratio setting is less than the settable range | Check that the ratio of function codes P00-17/P00-18, P00-19/P00-20 is in the following range. 17bit absolute encoder lower limit value: 0.001. |

Er.36 Position deviation is too large

Fault

| Servo drive panel display | Fault name |

|---|---|

| Position deviation is too large |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Cable error | Check whether the phase sequence of the motor power cable on the servo driver side and motor side corresponds to each other. | Connect correctly according to UVW on the drive side and UVW on the motor side |

| Check whether both ends of the power cable are disconnected | Replace the power cable and power on again | |

| Unreasonable parameter settings | Check whether P03-02 (Load rigidity Level) is set properly | Reduce the P03-02 (load stiffness level) setting value appropriately |

| Check whether the gain parameters are set properly, resulting in overshoot | Adjust gain parameters reasonably | |

| Check whether P00-25 (position deviation threshold) is set properly | Increase the value of P00-25 (position deviation threshold) | |

| Use Wecon SCTools to obtain the equivalent speed of the position instruction and check whether the speed is greater than the motor speed limit | Increase the setting values of P01-12 (forward speed threshold) and P01-13 (reverse speed threshold) according to mechanical requirements | |

| Motor blockage | Check if the motor is blocked due to mechanical jamming of the load. | Release the mechanical jam. |

| The brakes are not open | Check whether the brake device is opened normally, and check whether the output voltage of the brake is 24V | Check the logic of brake power supply or brake output signal |

| The input pulse frequency is too high | Position mode: when the instruction comes from the pulse instruction (P01-06=0), check whether the input pulse frequency is too high | Reduce the input pulse frequency |

| The equivalent velocity of position instruction changes too fast | Check if the position instruction changes too fast in the equivalent speed | Properly increase the acceleration and deceleration time and reduce the rate of change of the speed |

Er.37 Torque saturation abnormal

Fault

| Servo drive panel display | Fault name |

|---|---|

| Torque saturation abnormal |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Motor power line cable UVW phase sequence error | Check whether the phase sequence of the motor power cable on the servo driver side and motor side corresponds to each other. | Connect correctly according to UVW on the drive side and UVW on the motor side |

| Unreasonable parameter settings | Check whether P01-19 Torque saturation timeout) is set properly | Increase P01-19 Torque saturation timeout) setting value appropriately |

| Check whether P01-15 (forward torque limit) and P01-16 (reverse torque limit) are set reasonable | Increase the setting values of P01-15 (forward torque limit) and P01-16 (reverse torque limit) appropriately | |

| Check whether the gain parameters are set properly | Adjust gain parameters reasonably | |

| Check whether the gain parameters are set properly | Increase the acceleration and deceleration time | |

| The load is too heavy | Check whether the load is too heavy | Reduce the load |

| Motor blockage | Check whether the motor is blocked due to mechanical jamming of the load. | Release the mechanical jam. |

| The brakes are not open | Check whether the brake device is opened normally, and check whether the output voltage of the brake is 24V | Check the logic of brake power supply or brake output signal |

| Limit switches are mounted outside the travel | Check whether the limit switch is installed outside the travel | Adjust the installation position of limit switch |

Er.38 Main circuit electricity is lack of phase

Fault

| Servo drive panel display | Fault name |

|---|---|

| Main circuit electricity is lack of phase |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Cable error | Check whether the motor power line connection port is connected reliably | Tighten the fixing screws of the motor power line connection ports |

| Check the power cable for disconnections at both ends | Replace the power cable and power on again. | |

| Three-phase specification drives run on single-phase power supplies | Check whether the three-phase drive has a single-phase power supply | Connect a three-phase power supply according to the power supply specifications |

| The power supply is unstable or off | Check that the drive input power specifications meet the specifications: 220V drive valid value: 198V to 242V. 380V drive valid value: 342V to 418V | Use after the power supply is stable. |

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged, please contact technician for repair. |

Er.39 Emergency stop

Fault

| Servo drive panel display | Fault name |

|---|---|

| Emergency stop |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drive receives emergency stop instructions | Check whether emergency stop protection is triggered manually | Power on the servo drive again |

Check whether the servo drive has mistakenly triggered the emergency stop signal. Check whether function 08 (E-STOP) is configured in the P06 group "DIDO configuration" function code group "DI port function selection" and whether the DI port wiring is normal. | Properly wire the DI port

|

Er.40 Encoder battery failure

Fault

| Servo drive panel display | Fault name |

|---|---|

| Encoder battery failure |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Multi-turn absolute encoder is not connected to the battery during the power off of the servo drive | Check if the encoder is connected to the battery during the power off of the servo | Set P10-03 (Fault clearing) to 1 |

| The voltage of multi-turn absolute encoder battery is low | Measure battery voltage | Contact technicians to replace with a new encoder battery |

Er.41 Motor (encoder) over temperature

Fault

| Servo drive panel display | Fault name |

|---|---|

| Motor (encoder) over temperature |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The motor is overloaded | Check whether the motor is overloaded | Reduce the load of the motor |

Er.42 Encoder write fault fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| Encoder write faults |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Poor contact of CN1 port | Check whether the cable port (CN1) of the encoder is properly connected | Tighten the fixing screws on the CN1 port |

| Check whether the servo drive CN1 port jack is deformed | If the cable is deformed, replace the cable or its port | |

| Poor contact on adapter port (Rectangular connection cable) | Check whether both ends of the rectangular connector are reliably connected | Make sure that both ends of the rectangular connector are connected reliably; Replace it with an encoder cable with higher connection reliability. |

| External interference | Check for strong magnetic fields nearby | Eliminate nearby strong magnetic interference |

| Check whether there are sources of interference such as power supply inverter equipment nearby | Separate strong and weak power as much as possible, with good ground contact between motor and servo drive, and keep away from power cable wiring. | |

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged, please contact technician for repair. |

Er.43 Drive overload fault

Fault

| Servo drive panel display | Fault name |

|---|---|

|

| Drive overload fault |

Troubleshooting

| Reason | Troubleshooting | Handling |

|---|---|---|

| The average output power (U0-34) exceeds the limit power (overload 110%) for more than 20 minutes. | Whether the average output power (U0-34) often exceeds the limit (overload 110) Check whether the drive meets the requirements. | Observed whether the U0-34 is often greater than the servo limit power (overload 110%) during servo operation. When ER.43 alarm is found in the process of machine adjustment, please check whether the servo power is suitable. It is recommended to replace the driver model with higher power. |

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged, contact the manufacturer's technician for repair. |

Er.44 Return to origin timeout failure

Fault

| Servo drive panel display | Fault name |

| Return to origin timeout failure |

Troubleshooting

| Reason | Troubleshooting | Treatment |

| Return-to-origin switch failure | Checks if the origin regression was always in high-speed search, and not low-speed search; | First confirm whether the PI function 26 is set by the P06 group, then check the DI terminal connection, and when manually changing the DI terminal logic, check whether the servo driver receives the corresponding DI level signal through U0-17. If it is not received, it means that the DI switch is wired incorrectly, please wire it correctly; when manually changing the logic of the DI terminal, if there is a received level signal, it means that there is an error in the origin regression operation, please operate it correctly. |

| Checks if the origin regression high-speed search has been in the reverse low-speed search process. | ||

| The speed of searching for the origin switch signal at high speed is too small | Check if the P01-41 setting value is too small | Servo drive may be damaged, contact manufacturer technician for repair. |

| Unreasonable hardware switch settings | Confirm whether the limit switch signals on both sides are in valid at the same time; | Set hardware switch positions reasonably. |

| Confirm whether a certain limit switch signal is valid at the same time as the deceleration point signal or the origin signal. |

Er.45 Drive Blocking Overtemperature Protection

Fault

| Servo drive panel display | Fault name |

|---|---|

| Driver Blocking Overtemperature Protection |

Troubleshooting

| Reason | Troubleshooting | Treatment |

|---|---|---|

| Check whether U0-39 load torque percentage exceeds the maximum torque of the motor for 3 seconds or observe whether the load torque at the waveform interface of the oscilloscope of the upper computer is greater than the maximum torque of the motor and the motor is blocked. | Check whether U0-39 load torque percentage exceeds the maximum torque of the motor, and observe whether the motor is stuck. | Observable maximum torque observe whether the load torque on the waveform interface of the host computer oscilloscope is greater than the motor maximum torque or check whether U0-39 load torque percentage exceeds the motor maximum torque for 3 seconds. |

Er.60 ADC conversion is not complete

Fault

| Servo drive panel display | Fault name |

|---|---|

| ADC conversion is not complete |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| External interference | Check for strong magnetic fields nearby | Eliminate nearby strong magnetic interference |

| Check whether there are sources of interference such as power supply inverter equipment nearby | Separate strong and weak power as much as possible, with good ground contact between motor and servo drive, and keep away from power cable wiring. | |

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.61 Internal software fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| Internal software fault |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.62 Internal software fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| Internal software fault |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.63 Internal software fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| Internal software fault |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.64 Internal software fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| Internal software fault |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

Er.65 Internal software fault

Fault

| Servo drive panel display | Fault name |

|---|---|

| Internal software fault |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Servo drive fault | Factory reset the parameter (P10-02=1) and power on again. If the servo drive still alarms after multiple operations, it is faulty. | If there is still alarm after multiple power-on, contact the technician. |

A-80 Drive overpower warning

Fault

| Servo drive panel display | Alarm name |

|---|---|

| Drive overpower warning |

Troubleshooting

| Reason | Troubleshooting | Handling |

The average output power (U0-34) exceeds the limit power of the drive (overload 110%) for more than 5 seconds, the drive will have alarm.

| Check whether the average output power (U0-34) exceeds the limit (overload 110) The average output power (U0-34) exceeds the limit power (overload 110%) for more than 5 minutes. Check whether the U0-34 exceeds 110% of the rated power of the driver. | Check whether the U0-34 exceeds 110% of the rated power of the driver. When A80 alarm is found in the process of machine adjustment, please check whether the servo power is suitable. |

| Servo-drive Model | Power rating/W | Limit power/W(110%overload) |

| VD2-010SA1G/SA1H | 400 | 440 |

| VD2-014SA1G/SA1H | 750 | 825 |

| VD2-016SA1G/SA1H | 1500 | 1650 |

| VD2-019SA1G/SA1H | 2300 | 2530 |

| VD2-021SA1G/SA1H | 2300 | 2530 |

| VD2-025SA1G/SA1H | 2600 | 2860 |

| VD2-030SA1G/SA1H | 2600 | 2860 |

| VD2F-010SA1P | 400 | 440 |

| VD2F-014SA1P | 750 | 825 |

| VD2-016TA1G/TA1H | 1500 | 1650 |

| VD2-019TA1G/TA1H | 2000 | 2200 |

| VD2-021TA1G /TA1H | 3000 | 3300 |

| VD2-030TA1G | 4000 | 4400 |

| VD2-040TA1G | 6000 | 6600 |

| VD2-050TA1G | 7500 | 8250 |

| VD2L-010SA1P | 400 | 440 |

| VD2L-014SA1P | 750 | 825 |

A-81 Overspeed alarm

Fault

| Servo drive panel display | Fault name |

|---|---|

| Overspeed alarm |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Motor power line cable UVW phase sequence error | Check whether the phase sequence of the motor power cable on the servo driver side and motor side corresponds to each other. | Connect correctly according to UVW on the drive side and UVW on the motor side |

| P01-11 parameter setting is not proper | Check whether the value of P01-11 (warning speed threshold) is less than the max speed required for the operation of motor | Reset P01-11 (warning speed threshold) according to mechanical requirements |

| Input speed command is too high | Check whether the motor speed corresponding to the input command exceeds P01-11 (maximum speed threshold) | Reduce the input speed instruction according to the mechanical requirements; Reasonably increase P01-11 (warning speed threshold) |

A-82 Overload

Fault

| Servo drive panel display | Fault name |

|---|---|

| Overload |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Motor power cable, encoder cable wiring error | Check whether the motor power cable and encoder cable wiring are correct. | Connect them according to the correct connection method. Priority is given to the use of motor power lines and encoder cables as standard by manufacturers |

| The load is too large | Check overload characteristics of motor or servo drive | Reduce the load. Contact technical to obtain the appropriate capacity drive and motor model. |

| Motor model and servo driver do not match | Perform inertia identification and check the inertia ratio. | Contact technician to obtain the matching motor model. |

| Motor model and servo driver do not match | Check the monitoring quantity U0-53 (motor model code). | Contact technician to obtain the matching motor model. |

| Unreasonable parameters | Use Wecon SCTools to obtain the actual torque waveform and observe whether overshoot is obvious | Set the appropriate loop gain parameters |

| Observe whether the motor vibrates during operation | Set the appropriate rigidity level |

A-83 Braking resistor is over temperature or overloaded

Fault

| Servo drive panel display | Fault name |

|---|---|

| Braking resistor is over temperature or overloaded |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Improper connection of internal braking resistor | Check whether C, D are connected to the short cap and the contact is normal | When using an internal braking resistor, reliably connect the shorting cap or shorting wire between C and D |

| Improper connection of external braking resistor | Remove the external braking resistor and measure whether the resistance value is "∞” (infinity) | Replace the new external braking resistor. After ensuring that the resistance value of the resistor is the same as the nominal value, connect it in series between P+ and C. |

| The resistance value of the external braking resistor is too large | Test the actual external braking resistor resistance and compare it with the recommended braking resistor to make sure the actual resistance is not too large. | Use a suitable external braking resistor. |

| Improper parameter setting | When using an external braking resistor, check the following parameters. Whether P00-09 (braking resistor setting) is reasonable. P00-10 (external braking resistor resistance value) is reasonable. | Reasonable setting of P00-09 (braking resistor setting): P00-09=1 (use external braking resistor and natural cooling) P00-09 = 3 (do not use the braking resistor, all by capacitor absorption) P00-10 (external braking resistor resistance value) parameter value and the actual actual use of external braking resistor are consistent. |

A-84 Parameter modification that needs to be powered on again

Fault

| Servo drive panel display | Fault name |

|---|---|

| Parameter modification that needs to be powered on again |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Modified the effective timing to "power on again" parameter. | Check whether the servo drive has modified the parameter with the effective time "power on again". | Power on again |

A-86 Input pulse frequency is too high

Fault

| Servo drive panel display | Fault name |

|---|---|

| Input pulse frequency is too high |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The input pulse frequency is too high | Position mode; When the instruction source is pulse instructions (P01-06=0), check whether the input pulse frequency is too high | Reduce the input pulse frequency |

| Improper parameter setting | Check whether the parameter value of P01-16 (number of instruction pulses for one rotation of the motor) is greater than the actual demand value. | Reset P01-16 according to mechanical requirements (number of instruction pulses for one rotation of motor). |

| Check whether the parameter value of P01-17 to P01-20 (electronic gear ratio) is greater than the actual demand value. | Reset parameter of values P01-17 to P01-20 (electronic gear ratio) according to mechanical requirements |

A-88 Main circuit momentary power off

Fault

| Servo drive panel display | Fault name |

|---|---|

| Main circuit momentary power off |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| Power off | Check that the drive input power specifications meet the specifications: 220V drive valid value: 198V to 242V. 380V drive valid value: 342V to 418V | Use it after the power supply is stable |

| Servo drive fault | The servo drive is still faulty after power on again | Servo drive may be damaged, please contact technician for repair. |

A-89 DI port configuration is duplicate

Fault

| Servo drive panel display | Fault name |

|---|---|

| DI port configuration is duplicate |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The same non-zero DI function is assigned to multiple DI ports | Check whether the "DI port function selection" of the "DIDO Configuration" function code group of the P06 group is configured with the same DI function | Configuring each DI port for different DI functions and power on again. Configure the function of the unwanted DI ports to 0 (off) and power on again. Factory reset the parameter P10-02=1, and power on again. |

A-90 DI port configuration is duplicate

Fault

| Servo drive panel display | Fault name |

|---|---|

| DO port configuration i duplicate |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The same non-zero DO function is assigned to multiple DO ports | Check whether the "DO port function selection" of the "DIDO Configuration" function code group of the P06 group is configured with the same DO function | Configuring each DO port for different DO functions and power on again. Configure the function of the unwanted DO ports to 0 (off) and power on again. Factory reset the parameter P10-02=1, and power on again. |

A-91 Parameter modification is too frequent

Fault

| Servo drive panel display | Fault name |

|---|---|

| Parameter modification is too frequent (modification frequency allowed of function code: 6 hours/150 times Note: 32-bit function code: recorded as 2 times) |

Troubleshooting

| Reason | Troubleshooting | Handling |

| EEPROM writing frequency is too high | Check whether the host computer frequently modifies the parameters (modification frequency allowed of function code: 6 hours/150 times Note: 32-bit function code: recorded as 2 times)

| (1) During machine adjustment, A91 warning (6 hours/150 times) caused by manual frequent modification of function codes can be cleared through P10-03. In other cases, please check the PLC program (2) If A91 warning appears in the normal working mode of the machine, please check whether the PLC program frequently modifies the function code. (3) When the function code needs to be modified frequently, it is recommended to close Modbus write to EEPROM (P12-4 is set to 0) |

| external interference | Check for strong magnetic fields nearby | Eliminate nearby strong magnetic interference |

| Check whether there are sources of interference such as power supply inverter equipment nearby | Separate strong and weak power as much as possible, with good ground contact between motor and servo drive, and keep away from power cable wiring. | |

Increase the abnormal threshold setting of P0-31 encoder read-write check.

| Eliminate the A93 warning by increasing the exception threshold is suitable as a temporary solution. The disadvantage is that the motor may run in an unstable state. | |

| Encoder fault | Manually rotate the motor shaft counterclockwise or clockwise to observe whether the monitoring quantity U0-30 (electrical angle) changes regularly | If the value of U0-30 (electrical angle) changes abruptly or does not change, the encoder itself may have problems, please replace the motor or encoder. |

| Servo drive fault | ●Cross-verification. Use the normal motor, encoder cable to connect to the servo drive. If the servo drive still have alarm, it is servo fault. | Servo driver may be damaged, please contact the manufacturer's technician. |

A-92 Low encoder battery voltage warning

Fault

| Servo drive panel display | Fault name |

|---|---|

| Low encoder battery voltage warning |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| The encoder battery voltage is less than 3.1V | Measure the encoder battery voltage | Contact technician to replace a new encoder battery |

A-93 Abnormal and frequency of encoder read and write check is too high

Fault

| Servo drive panel display | Fault name |

|---|---|

| The abnormal frequency of encoder read-write verification is too high |

Troubleshooting

| Reason | Troubleshooting methods | Handling |

|---|---|---|

| External interference | Check for strong magnetic fields nearby | Eliminate nearby strong magnetic interference |

| Check whether there are sources of interference such as power supply inverter equipment nearby | Separate strong and weak power as much as possible, with good ground contact between motor and servo drive, and keep away from power cable wiring. | |

| Increase the abnormal threshold setting of P0-31. | This method is suitable as a temporary workaround to eliminate the A93 warning. It may cause an unstable state in the operation of the motor. | |

| Encoder issue | Manually rotate the motor shaft slowly, and observe the changes of the monitoring quantity U0-30 (electrical angle). | If the value of U0-30 (electrical angle) changes suddenly or does not change, it may be a problem with the encoder, please replace the motor or encoder. |

| Internal servo drive fault | Cross-verification. Use the normal motor, encoder cable to connect to the servo drive, only connect the encoder cable. If the servo drive still alarm, it is failure. | Contact technician for repair |