06 Operation

Basic settings

Check before operation

| No. | Content |

|---|---|

| Wiring | |

| 1 | The main circuit input terminals (L1, L2 and L3) of servo drive must be properly connected. |

| 2 | The main circuit output terminals (U, V and W) of servo drive and the main circuit cables (U, V and W) of servo motor must have the same phase and be properly connected. |

| 3 | The main circuit power input terminals (L1, L2 and L3) and the main circuit output terminals (U, V and W) of servo drive cannot be short-circuited. |

| 4 | The wiring of each control signal cable of servo drive is correct: The external signal wires such as brake and overtravel protection have been reliably connected. |

| 5 | Servo drive and servo motor must be grounded reliably. |

| 6 | When using an external braking resistor, the short wiring between drive C and D must be removed. |

| 7 | The force of all cables is within the specified range. |

| 8 | The wiring terminals have been insulated. |

| Environment and Machinery | |

| 1 | There is no iron filings, metal, etc. that can cause short circuits inside or outside the servo drive. |

| 2 | The servo drive and external braking resistor are not placed on combustible objects. |

| 3 | The installation, shaft and mechanical structure of the servo motor have been firmly connected. |

Table 6-1 Check contents before operation

Power-on

Connect the main circuit power supply

After powering on the main circuit, the bus voltage indicator shows no abnormality, and the panel display "rdy", indicating that the servo drive is in an operational state, waiting for the host computer to give the servo enable signal.

If the drive panel displays other fault codes, please refer to “10 Malfunctions"” to analyze and eliminate the cause of the fault.

Set the servo drive enable (S-ON) to invalid (OFF)

Jog operation

Jog operation is used to judge whether the servo motor can rotate normally, and whether there is abnormal vibration and abnormal sound during rotation. Jog operation can be realized in two ways, one is panel jog operation, which can be realized by pressing the buttons on the servo panel. The other is jog operation through the host computer debugging platform.

Panel jog operation

Enter “P10-01” by pressing the key on the panel. After pressing “OK”, the panel will display the current jog speed. At this time, you can adjust the jog speed by pressing the "up" or "down" keys; After adjusting the moving speed, press "OK", and the panel displays "JOG" and is in a flashing state. Press "OK" again to enter the jog operation mode (the motor is now powered on!). Long press the "up" and "down" keys to achieve the forward and reverse rotation of the motor. Press "Mode" key to exit the jog operation mode. For operation and display, please refer to "5.3.2. Jog operation".

Jog operation of servo debugging platform

Open the jog operation interface of the software “Wecon SCTool”, set the jog speed value in the "set speed" in the "manual operation", click the "servo on" button on the interface, and then achieve the jog forward and reverse function through the "forward rotation" or "Reverse" button on the interface. After clicking the "Servo off" button, the jog operation mode is exited. The related function codes are shown below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

P10-01 | JOG speed | Operation setting | Effective immediately | 100 | 0 to 3000 | JOG speed | rpm |

Table 6-2 JOG speed parameter

Rotation direction selection

By setting the “P00-04” rotation direction, you could change the rotation direction of the motor without changing the polarity of the input instruction. The function code is shown in below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

P00-04 | Rotation direction | Shutdown setting | Effective immediately | 0 | 0 to 2 | Forward rotation: Face the motor shaft to watch 0: standard setting (CW is forward rotation) 1: reverse mode (CCW is forward rotation) 2:reverse mode (CCW is forward rotation),set P1-12,P1-17 to limit the speed in CCW direction; set P1-13,P1-18 to limit the speed in CCW direction. ✎Note: VD2L driver P0-04 setting range: 0~1, P00-4=2 is not supported! | - |

Table 6-3 Rotation direction parameters

Braking resistor

The servo motor is in the generator state when decelerating or stopping, the motor will transfer energy back to the drive, which will increase the bus voltage. When the bus voltage exceeds the braking point, The drive can consume the feedback energy in the form of thermal energy through the braking resistor. The braking resistor can be built-in or externally connected, but it cannot be used at the same time. When selecting an external braking resistor, it is necessary to remove the short link on the servo drive.

The basis for judging whether the braking resistor is built-in or external.

- the maximum brake energy calculated value > the maximum brake energy absorbed by capacitor, and the brake power calculated value ≤ the built-in braking resistor power, use the built-in braking resistor.

- the maximum brake energy calculated value > the maximum brake energy absorbed by capacitor, and the brake power calculated value > the built-in braking resistor power, use external braking resistor.

| Function code | Name | Setting method | Effective time | Default | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P00-09 | Braking resistor setting | Operation setting | Effective immediately | 0 | 0 to 3 | 0: use built-in braking resistor 1: use external braking resistor and natural cooling 2: use external braking resistor and forced air cooling; (cannot be set) 3: No braking resistor is used, it is all absorbed by capacitor. | - |

| ✎Note: VD2-010SA1G , VD2F-030SA1P-010SA1P and VD2L-010SA1P drives have no built-in resistor by default, so the default value of the function code “P00-09” is 3 (No braking resistor is used, it is all absorbed by capacitor). | |||||||

| P00-10 | External braking resistor value | Operation setting | Effective immediately | 50 | 0 to 65535 | It is used to set the external braking resistor value of a certain type of drive. | Ω |

| P00-11 | External braking resistor power | Operation setting | Effective immediately | 100 | 0 to 65535 | It is used to set the external braking resistor power of a certain type of drive. | W |

Table 6-4 Braking resistor parameters

Servo operation

Set the servo enable (S-ON) to valid (ON)

The servo drive is in a running state and displays "run", but because there is no instruction input at this time, the servo motor does not rotate and is locked.

S-ON can be configured and selected by the DI terminal function selection of the function code "DIDO configuration".

Input the instruction and the motor rotates

Input appropriate instructions during operation, first run the motor at a low speed, and observe the rotation to see if it conforms to the set rotation direction. Observe the actual running speed, bus voltage and other parameters of the motor through the host computer debugging platform. According to "7 Adjustment", the motor could work as expected.

Timing diagram of power on

Figure 6-1 Timing diagram of power on

Servo shutdown

According to the different shutdown modes, it could be divided into free shutdown and zero speed shutdown. The respective characteristics are shown in Table 6-5. According to the shutdown status, it could be divided into free running state and position locked, as shown in Table 6-6.

| Shutdown mode | Shutdown description | Shutdown characteristics |

|---|---|---|

| Free stop | Servo motor is not energized and decelerates freely to 0. The deceleration time is affected by factors such as mechanical inertia and mechanical friction. | Smooth deceleration, small mechanical shock, but slow deceleration process. |

| Zero-speed shutdown | The servo drive outputs reverse braking torque, and the motor quickly decelerates to zero-speed. | Rapid deceleration with mechanical shock, but fast deceleration process. |

Table 6-5 Comparison of two shutdown modes

| Shutdown status | Free operation status | Position locked |

|---|---|---|

| Characteristics | After the motor stops rotating, it is power-off, and the motor shaft can rotate freely. | After the motor stops rotating, the motor shaft is locked and could not rotate freely. |

Table 6-6 Comparison of two shutdown status

Servo enable (S-ON) OFF shutdown

The related parameters of the servo OFF shutdown mode are shown in the table below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P00-05 | Servo OFF shutdown | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: Free stop, and the motor shaft remains free status. 1: Zero-speed stop, and the motor axis remains free status. | - |

Table 6-7 Servo OFF shutdown mode parameters details

Emergency shutdown

It is free shutdown mode at present, and the motor shaft remains in a free state. The corresponding configuration and selection could be selected through the DI terminal function of the function code "DIDO configuration". The V1.18 firmware version adds the Estop stop time setting function. In some occasions where the servo needs to control the emergency stop of the motor, it is necessary to control the emergency stop time of the DI. Therefore, the P01-05 shutdown deceleration time function is added to deal with this situation.

Estop mode 1 (deceleration stop):

1. Configurate DI function code: 8 [ESTOP]

2. Set P1-5 shutdown deceleration time.

3. Trigger DI emergency shutdown.

4. Servo emergency shutdown and deceleration to zero speed.

Estop mode 2:

1. Configurate DI function code: 1 [Servo enable SON]

2. Set P1-05 shutdown deceleration time.

3. Set P0-05 Servo OFF shutdown mode: zero speed stop.

4. Trigger DI to turn off servo enable SON.

5.Servo enable turns off and stops and decelerates to zero speed.

| Function code | Name | Setting method | Effective time | Default | Range | Definition | Unit |

| P01-05 | Shutdown deceleration time | Shutdown setting | immediately Effective | 50 | 0 to 65535 | The time for the speed command to decelerate from 1000rpm to 0 | ms |

Table 6-8 Downtime deceleration time parameter details

Overtravel shutdown

Overtravel means that the movable part of the machine exceeds the set area. In some occasions where the servo moves horizontally or vertically, it is necessary to limit the movement range of the workpiece. The overtravel is generally detected by limit switches, photoelectric switches or the multi-turn position of the encoder, that is, hardware overtravel or software overtravel.

Once the servo drive detects the action of the limit switch signal, it will immediately force the speed in the current direction of rotation to 0 to prevent it from continuing, and it will not be affected for reverse rotation. The overtravel shutdonw is fixed at zero speed and the motor shaft remains locked.

The corresponding configuration and selection could be selected through the DI terminal function of the function code "DIDO configuration". The default function of DI3 is POT and DI4 is NOT, as shown in the table below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P06-08 | DI_3 channel function selection | Operation setting | Power-on again | 3 | 0 to 32 | 0: OFF (not used) 01: S-ON servo enable 02: A-CLR fault and Warning Clear 03: POT forward drive prohibition 04: NOT Reverse drive prohibition 05: ZCLAMP Zero speed 06: CL Clear deviation counter 07: C-SIGN Inverted instruction 08: E-STOP Emergency stop 09: GEAR-SEL Electronic Gear Switch 1 10: GAIN-SEL gain switch 11: INH Instruction pulse prohibited input 12: VSSEL Vibration control switch input 13: INSPD1 Internal speed instruction selection 1 14: INSPD2 Internal speed instruction selection 2 15: INSPD3 Internal speedinstruction selection 3 16: J-SEL inertia ratio switch (not implemented yet) 17: MixModesel mixed mode selection 20: Internal multi-segment position enable signal 21: Internal multi-segment position selection 1 22: Internal multi-segment position selection 2 23: Internal multi-segment position selection 3 24: Internal multi-segment position selection 4 Others: reserved | - |

| P06-09 | DI_3 channel logic selection | Operation setting | Effective immediately | 0 | 0 to 1 | DI port input logic validity function selection. 0: Normally open input. Low level valid (switch on); 1: Normally closed input. High level valid (switch off); | - |

| P06-10 | DI_3 input source selection | Operation setting | Effective immediately | 0 | 0 to 1 | Select the DI_3 port type to enable 0: Hardware DI_3 input terminal 1: Virtual VDI_3 input terminal | - |

| P06-11 | DI_4 channel function selection | Operation setting | Power-on again | 4 | 0 to 32 | 0: OFF (not used) 01: SON Servo enable 02: A-CLR Fault and Warning Clear 03: POT Forward drive prohibition 04: NOT Reverse drive prohibition 05: ZCLAMP Zero speed 06: CL Clear deviation counter 07: C-SIGN Inverted instruction 08: E-STOP Emergency shutdown 09: GEAR-SEL Electronic Gear Switch 1 10: GAIN-SEL gain switch 11: INH Instruction pulse prohibited input 12: VSSEL Vibration control switch input 13: INSPD1 Internal speed instruction selection 1 14: INSPD2 Internal speed instruction selection 2 15: INSPD3 Internal speed instruction selection 3 16: J-SEL inertia ratio switch (not implemented yet) 17: MixModesel mixed mode selection 20: Internal multi-segment position enable signal 21: Internal multi-segment position selection 1 22: Internal multi-segment position selection 2 23: Internal multi-segment position selection 3 24: Internal multi-segment position selection 4 Others: reserved | - |

| P06-12 | DI_4 channel logic selection | Operation setting | Effective immediately | 0 | 0 to 1 | DI port input logic validity function selection. 0: Normally open input. Low level valid (switch on); 1: Normally closed input. High level valid (switch off); | - |

| P06-13 | DI_4 input source selection | Operation setting | Effective immediately | 0 | 0 to 1 | Select the DI_4 port type to enable 0: Hardware DI_4 input terminal 1: Virtual VDI_4 input terminal | - |

Table 6-9 DI3 and DI4 channel parameters

(4) Malfunction shutdown

When the machine fails, the servo will perform a fault shutdown operation. The current shutdown mode is fixed to the free shutdown mode, and the motor shaft remains in a free state.

Brake device

The brake is a mechanism that prevents the servo motor shaft from moving when the servo drive is in a non-operating state, and keeps the motor locked in position, so that the moving part of the machine will not move due to its own weight or external force.

|

✎The brake device is built into the servo motor, which is only used as a non-energized fixed special mechanism. It cannot be used for braking purposes, and can only be used when the servo motor is kept stopped; ✎ After the servo motor stops, turn off the servo enable (S-ON) in time; ✎The brake coil has no polarity; ✎When the brake coil is energized (that is, the brake is open), magnetic flux leakage may occur at the shaft end and other parts. If users need to use magnetic sensors and other device near the motor, please pay attention! ✎When the motor with built-in brake is in operation, the brake device may make a clicking sound, which does not affect the function. |

Wiring of brake device

The brake input signal has no polarity. User need to prepare a 24V power supply. The standard connection of brake signal BK and brake power supply is shown in the figure below. (take VD2B servo drive as example)

Figure 6-2 VD2B servo drive brake wiring

|

✎The length of the motor brake cable needs to fully consider the voltage drop caused by the cable resistance, and the brake operation needs to ensure that the voltage input is 24V. ✎It is recommended to use the power supply alone for the brake device. If the power supply is shared with other electrical device, the voltage or current may decrease due to the operation of other electrical device, which may cause the brake to malfunction. ✎It is recommended to use cables above 0.5 mm². |

Brake software setting

For a servo motor with brake, one DO terminal of servo drive must be configured as function 141 (BRK-OFF, brake output), and the effective logic of the DO terminal must be determined.

Related function code is as below.

| DO function code | Function name | Function | Effective time |

|---|---|---|---|

| 141 | BRK-OFF Brake output | Output the signal indicates the servo motor brake release | Power-on again |

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P1-30 | Delay from brake output to instruction reception | Operation setting | Effective immediately | 250 | 0 to 500 | Set delay that from the brake (BRK-OFF) output is ON to servo drive allows to receive input instruction. When brake output (BRK-OFF) is not allocated, the function code has no effect. | ms |

| P1-31 | In static state, delay from brake output OFF to the motor is power off | Operation setting | Effective immediately | 150 | 1 to 1000 | When the motor is in a static state, set the delay time from brake (BRK-OFF) output OFF to servo drive enters the non-channel state. When the brake output (BRK-OFF) is not allocated, this function code has no effect. | ms |

| P1-32 | Rotation status, when the brake output OFF, the speed threshold | Operation setting | Effective immediately | 30 | 0 to 3000 | When the motor rotates, the motor speed threshold when the brake (BRK-OFF) is allowed to output OFF. When the brake output (BRK-OFF) is not allocated, this function code has no effect. | rpm |

| P1-33 | Rotation status, Delay from servo enable OFF to brake output OFF | Operation setting | Effective immediately | 500 | 1 to 1000 | When the motor rotates, the delay time from the servo enable (S-ON) OFF to the brake (BRK-OFF) output OFF is allowed. When brake output (BRK-OFF) is not allocated, this function code has no effect. | ms |

Table 6-10 Relevant function codes for brake setting

According to the state of servo drive, the working sequence of the brake mechanism can be divided into the brake sequence in the normal state of the servo drive and the brake sequence in the fault state of the servo drive.

Servo drive brake timing in normal state

The brake timing of the normal state could be divided into: the servo motor static (the actual speed of motor is lower than 20 rpm) and servo motor rotation(the actual speed of the motor reaches 20 and above).

- Brake timing when servo motor is stationary

When the servo enable changes from ON to OFF, if the actual motor speed is lower than20 rpm, the servo drive will act according to the static brake sequence. The specific sequence action is shown in Figure 6-3

|

✎After the brake output is from OFF to ON, within P01-30, do not input position/speed/torque instructions, otherwise the instructions will be lost or operation errors will be caused. ✎When applied to a vertical axis, the external force or the weight of the mechanical moving part may cause the machine to move slightly. When the servo motor is stationary, and the servo enable is OFF, the brake output will be OFF immediately. However, the motor is still energized within the time of P01-31 to prevent mechanical movement from moving due to its own weight or external force. |

Figure 6-3 Brake Timing of when the motor is stationary

- The brake timing when servo motor rotates

When the servo enable is from ON to OFF, if the actual motor speed is greater than or equal to 20 rpm, the drive will act in accordance with the rotation brake sequence. The specific sequence action is shown in Figure 6-4.

|

✎When the servo enable is turned from OFF to ON, within P1-30, do not input position, speed or torque instructions, otherwise the instructions will be lost or operation errors will be caused. ✎When the servo motor rotates, the servo enable is OFF and the servo motor is in the zero-speed shutdown state, but the brake output must meet any of the following conditions before it could be set OFF: P01-33 time has not arrived, but the motor has decelerated to the speed set by P01-32; P01-33 time is up, but the motor speed is still higher than the set value of P01-32. ✎After the brake output changes from ON to OFF, the motor is still in communication within 50ms to prevent the mechanical movement from moving due to its own weight or external force. |

Figure 6-4 Brake timing when the motor rotates

Brake timing when the servo drive fails

The brake timing (free shutdown) in the fault status is as follows.

Figure 6-5 The brake timing (free shutdown) in the fault state

✎Note: The "delay arrival" of the brake signal is about 20ms, and the actual parameter is subject to the motor manufacturer

Position control mode

Position control is the most important and commonly used control mode of the servo system. Position control refers to controlling the position of the motor through position instructions, and determining the target position of the motor by the total number of position instructions. The frequency of the position instruction determines the motor rotation speed. The servo drive can achieve fast and accurate control of the position and speed of the machine. Therefore, the position control mode is mainly used for occasions that require positioning control, such as manipulators, mounter, engraving machines, CNC machine tools, etc. The position control block diagram is shown in the figure below.

Figure 6-6 Position control diagram

Set “P00-01” to 1 by the software “Wecon SCTool”, and the servo drive is in position control mode.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P00-01 | Control mode | Operation setting | immediately Effective | 1 | 1 to 6 | 1: position control 2: speed control 3: torque control 4: position/speed mix control 5: position/torque mix control 6: speed /torque mix control VD2L drive P00-01 setting range: 1-3, not supprt mix mode | - |

Table 6-11 Control mode parameters

Position instruction input setting

When the VD2 series servo drive is in position control mode, firstly set the position instruction source through the function code “P01-06”.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-06 | Position instruction source | Operation setting | immediately Effective | 0 | 0 to 1 | 0: pulse instruction 1: internal position instruction | - |

Table 6-12 Position instruction source parameter

The source of position instruction is pulse instruction (P01-06=0)

Low-speed pulse instruction input

VD2A, VD2B and VD2C servo drives |  VD2F and VD2L servo drive |

| Figure 6-7 Position instruction input setting | |

VD2 series servo drive has a set of pulse input terminals to receive the input of position pulse (via the CN2 terminal). The position pulse mode connection is shown in Figure 6-7.

The instruction pulse and symbol output circuit on the control device(HMI/PLC) side could select differential input or open collector input. The maximum input frequency is shown as below.

| Pulse method | Maximum frequency | Voltage |

|---|---|---|

| Open collector input | 200K | 24V |

| Differential input | 500K | 5V |

Table 6-13 Pulse input specifications

- Differential input

Take VD2A , VD2B and VD2C drive as examples, the connection of differential input is shown as below.

Figure 6-8 Differential input connection

- Open collector input

Take VD2A, VD2B and VD2C drive as examples, the connection of differential input is shown as below.

Figure 6-9 Open collector input connection

- Position pulse frequency and anti-interference level

When low-speed pulses input pins, you need to set a certain pin filter time to filter the input pulse instructions to prevent external interference from entering the servo drive and affecting motor control. After the filter function is enabled, the input and output waveforms of the signal are shown in Figure 6-10.

Figure 6-10 Example of filtered signal waveform

The input pulse frequency refers to the frequency of the input signal, which can be modified through the function code “P00-13”. If the actual input frequency is greater than the set value of “P00-13”, it may cause pulse loss or alarm. The position pulse anti-interference level can be adjusted through the function code “P00-14”, the larger the set value, the greater the filtering depth. The details of related function code parameters are as shown in Table 6-14.

✎Note:The parameter of VD2L P00-14 is different from other models in the VD2 series.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit | |

|---|---|---|---|---|---|---|---|---|

| P00-14 | Position pulse anti-interference level | Operation setting | Power-on again | 2 | 0 to 9 | Set the anti-interference level of external pulse instruction. 0: no filtering; 1: Filtering time 128ns 2: Filtering time 256ns 3: Filtering time 512ns 4: Filtering time 1.024us 5: Filtering time 2.048us 6: Filtering time 4.096us 7: Filtering time 8.192us 8: Filtering time 16.384us 9: VD2: Filtering time 32.768us VD2F: Filtering time 25.5us | - | |

Table 6-14 Position pulse frequency and anti-interference level parameters

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

| P00-14 | Position pulse anti-interference level | Operation setting | Power-on again | 3 | 0 to 8 | VD2L drive set the anti-interference level of external pulse instruction. 0: no filtering; 1: Filtering time 111.1ns 2: Filtering time 222.2ns 3: Filtering time 444.4ns 4: Filtering time 888.8ns 5: Filtering time 1777.7ns 6: Filtering time 3555.5ns 7: Filtering time 7111.7ns 8: Filtering time 14222.2ns

| - |

Table 6-15 VD2L Position pulse frequency and anti-interference level parameters

- Position pulse type selection

In VD2 series servo drives, there are three types of input pulse instructions, and the related function codes are shown in the table below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P00-12 | Position pulse type selection | Operation setting | Power-on again | 0 | 0 to 5 | 0: direction + pulse (positive logic) 1: CW/CCW 2: A, B phase quadrature pulse (4 times frequency) 3: Direction + pulse (negative logic) 4: CW/CCW (negative logic) 5: A, B phase quadrature pulse (4 times frequency negative logic) ✎Note: VD2F and VD2L series drivers do not support the pulse form of CW/CCW! P0-12 parameter setting range of VD2L: 0, 2, 3, 5 | - |

Table 6-16 Position pulse type selection parameter

| Pulse type selection | Pulse type | Signal | Schematic diagram of forward pulse | Schematic diagram of negative pulse |

|---|---|---|---|---|

| 0 | Direction + pulse (Positive logic) | PULSE SIGN |  |  |

| 1 | CW/CCW | PULSE (CW) SIGN (CCW) |  | |

| 2 | AB phase orthogonal pulse (4 times frequency) | PULSE (Phase A) SIGN (Phase B) |

Phase A is 90° ahead of Phase B |

Phase B is 90° ahead of Phase A |

| 3 | Direction + pulse (Negative logic) | PULSE SIGN |  |  |

| 4 | CW/CCW (Negative logic) | PULSE (CW) SIGN (CCW) |  | |

| 5 | AB phase orthogonal pulse (4 times frequency negative logic) | PULSE (Phase A) SIGN (Phase B) |

Phase B is ahead of A phase by 90° |

Phase A is ahead of B phase by 90° |

Table 6-17 Pulse description

The source of position instruction is internal position instruction (P01-06=1)

The VD2 series servo drive has a multi-segment position operation function, which supports maximum 16-segment instructions. The displacement, maximum operating speed (steady-state operating speed) and acceleration/deceleration time of each segment could be set separately. The waiting time between positions could also be set according to actual needs. The setting process of multi-segment position is shown in Figure 6-11.

The servo drive completely runs the multi-segment position instruction set by P07-01 once, and the total number of positions is called completing one round of operation.

Figure 6-11 The setting process of multi-segment position

- Set multi-segment position running mode

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P07-01 | Multi-segment position running mode | Shutdown setting | Effective immediately | 0 | 0 to 2 | 0: Single running 1: Cycle running 2: DI switching running | - |

| P07-02 | Start segment number | Shutdown setting | Effective immediately | 1 | 1 to 16 | 1st segment NO. in non-DI switching mode | - |

| P07-03 | End segment number | Shutdown setting | Effective immediately | 1 | 1 to 16 | last segment NO. in non-DI switching mode | - |

| P07-04 | Margin processing method | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: Run the remaining segments 1: Run again from the start segment | - |

| P07-05 | Displacement instruction type | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: Relative position instruction 1: Absolute position instruction | - |

Table 6-18 multi-segment position running mode parameters

VD2 series servo drive has three multi-segment position running modes, and you could select the best running mode according to the site requirements.

- Single running

In this running mode, the segment number is automatically incremented and switched, and the servo drive only operates for one round (the servo drive runs completely once for the total number of multi-segment position instructions set by P07-02 and P07-03). The single running curve is shown in Figure 6-12, and S1 and S2 are the displacements of the 1st segment and the 2nd segment respectively

Figure 6-12 Single running curve (P07-02=1, P07-03=2)

- 2. Cycle running

In this running mode, the position number is automatically incremented and switched, and the servo drive repeatedly runs the total number of multi-segment position instructions set by P07-02 and P07-03. The waiting time could be set between each segment. The cycle running curve is shown in Figure 6-13, and S1,S2,S3 and S4 are the displacements of the 1st, 2nd, 3rd and 4th segment respectively.

Figure 6-13 Cycle running curve (P07-02=1, P07-03=4)

|

| In single running and cycle running mode, the setting value of P07-03 needs to be greater than the setting value of P07-02. |

- DI switching running

In this running mode, the next running segment number could be set when operating the current segment number. The interval time is determined by the instruction delay of the host computer. The running segment number is determined by DI terminal logic, and the related function codes are shown in the table below.

| DI function code | Function name | Function |

|---|---|---|

| 21 | INPOS1: Internal multi-segment position segment selection 1 | Form internal multi-segment position running segment number |

| 22 | INPOS2: Internal multi-segment position segment selection 2 | Form internal multi-segment position running segment number |

| 23 | INPOS3: Internal multi-segment position segment selection 3 | Form internal multi-segment position running segment number |

| 24 | INPOS4: Internal multi-segment position segment selection 4 | Form internal multi-segment position running segment number |

Table 6-19 DI function code

The multi-segment segment number is a 4-bit binary number, and the DI terminal logic is level valid. When the input level is valid, the segment selection bit value is 1, otherwise it is 0. Table 6-17 shows the correspondence between the position bits 1 to 4 of the internal multi-segment position and the position number.

| INPOS4 | INPOS3 | INPOS2 | INPOS1 | Running position number |

|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 1 |

| 0 | 0 | 0 | 1 | 2 |

| 0 | 0 | 1 | 0 | 3 |

| 0 | 0 | 1 | 1 | 4 |

| 0 | 1 | 0 | 0 | 5 |

| 0 | 1 | 0 | 1 | 6 |

| 0 | 1 | 1 | 0 | 7 |

| 0 | 1 | 1 | 1 | 8 |

| 1 | 0 | 0 | 0 | 9 |

| 1 | 0 | 0 | 1 | 10 |

| 1 | 0 | 1 | 0 | 11 |

| 1 | 0 | 1 | 1 | 12 |

| 1 | 1 | 0 | 0 | 13 |

| 1 | 1 | 0 | 1 | 14 |

| 1 | 1 | 1 | 0 | 15 |

| 1 | 1 | 1 | 1 | 16 |

Table 6-20 INPOS corresponds to running segment number

The operating curve in this running mode is shown in Figure 6-14.

Figure 6-14 DI switching running curve

VD2 series servo drives have two margin processing methods: run the remaining segments and run from the start segment again. The related function code is P07-04.

Run the remaining segments

In this processing way, the multi-segment position instruction enable is OFF during running, the servo drive will abandon the unfinished displacement part and shutdown, and the positioning completion signal will be valid after the shutdown is complete. When the multi-segment position enable is ON, and the servo drive will start to run from the next segment where the OFF occurs. The curves of single running and cycle running are shown in Figure 6-15 and Figure 6-16 respectively.

Figure 6-15 Single running-run the remaining segments (P07-02=1, P07-03=4)

Figure 6-16 Cycle running-run the remaining segment (P07-02=1, P07-03=4)

Run again from the start segment

In this processing mode, when the multi-segment position instruction enable is OFF during running, the servo drive will abandon the uncompleted displacement part and shutdown. After the shutdown is completed, the positioning completion signal is valid. When the multi-segment position enable is ON, and the servo drive will start to operate from the next position set by P07-02. The curves of single running and cycle running are shown in Figure 6-17 and Figure 6-18 respectively.

Figure 6-17 Single running-run from the start segment again (P07-02=1, P07-03=4)

Figure 6-18 Cyclic running-run from the start segment again (P07-02=1, P07-03=4)

VD2 series servo drives have two types of displacement instructions: relative position instruction and absolute position instruction. The related function code is P07-05.

- Relative position instruction

The relative position instruction takes the current stop position of the motor as the start point and specifies the amount of displacement.

Figure 6-19 Relative position diagram |  Figure 6-20 Displacement diagram |

- Absolute position instruction

The absolute position instruction takes "reference origin" as the zero point of absolute positioning, and specifies the amount of displacement.

Figure 6-21 Absolute indication |  Figure 6-22 Displacement |

- Multi-segment position running curve setting

The multi-segment position running supports maximum 16 segments different position instructions. The displacement, maximum running speed (steady-state running speed), acceleration and deceleration time of each position and the waiting time between segment could all be set. Table 6-21 are the related function codes of the 1st segment running curve.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P07-09 | 1st segment displacement | Operation setting | Effective immediately | 10000 | -2147483647 to 2147483646 | Position instruction, positive and negative values could be set | - |

| P07-10 | Maximum speed of the 1st displacement | Operation setting | Effective immediately | 100 | 1 to 5000 | Steady-state running speed of the 1st segment | rpm |

| P07-11 | Acceleration and deceleration of 1st segment displacement | Operation setting | Effective immediately | 100 | 1 to 65535 | The time required for the acceleration and deceleration of the 1st segment | ms |

| P07-12 | Waiting time after completion of the 1st segment displacement | Operation setting | Effective immediately | 100 | 1 to 65535 | Delayed waiting time from the completion of the 1st segment to the start of the next segment | Set by P07-06 |

Table 6-21 The 1st position operation curve parameters table

After setting the above parameters, the actual operation curve of the motor is shown in Figure 6-23.

Figure 6-23 The 1st segment running curve of motor

- multi-segment position instruction enable

When selecting multi-segment position instruction as the instruction source, configure 1 DI port channel of the servo drive to function 20 (internal multi-segment position enable signal), and confirm the valid logic of the DI terminal.

| DI function code | Function name | Function |

|---|---|---|

| 20 | ENINPOS: Internal multi-segment position enable signal | DI port logic invalid: Does not affect the current operation of the servo motor. DI port logic valid: Motor runs multi-segment position |

It should be noted that only when the internal multi-segment position enable signal is OFF, can the P07 group parameters be actually modified to write into the servo drive!

Electronic gear ratio

Definition of electronic gear ratio

In the position control mode, the input position instruction (instruction unit) is to set the load displacement, and the motor position instruction (encoder unit) is to set the motor displacement, in order to establish the proportional relationship between the motor position instruction and the input position instruction, electronic gear ratio function is used. "instruction unit" refers to the minimum resolvable value input from the control device(HMI/PLC) to the servo drive. "Encoder unit" refers to the value of the input instruction processed by the electronic gear ratio.

With the function of the frequency division (electronic gear ratio <1) or multiplication (electronic gear ratio > 1) of the electronic gear ratio, the actual the motor rotation or movement displacement can be set when the input position instruction is 1 instruction unit.

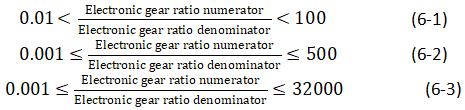

It it noted that the electronic gear ratio setting range of the 2500-line incremental encoder should meet the formula (6-1), and the electronic gear ratio setting range of the 17-bit encoder should meet the formula (6-2), setting range of the electronic gear ratio of 23-bit encoder should meet the formula (6-3)

Otherwise, the servo drive will report Er.35: "Electronic gear ratio setting exceeds the limit"!

Setting steps of electronic gear ratio

Figure 6-24 Setting steps of electronic gear ratio

lectronic gear ratio switch setting

When the function code P00-16 is 0, the electronic gear ratio switching function could be used. You could switch between electronic gear 1 and electronic gear 2 as needed. There is only one set of gear ratios at any time. Related function codes are shown in the table below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P00-16 | Number of instruction pulses when the motor rotates one circle | Shutdown setting | Effective immediately | 10000 | 0 to 131072 | Set the number of position command pulses required for each turn of the motor. When the setting value is 0, [P00-17]/[P00-19] Electronic gear 1/2 numerator, [P00-18]/[P00-20] Electronic gear 1/2 denominator is valid. | Instruction pulse unit |

| P00-17 | Electronic gear 1 numerator | Operation setting | Effective immediately | 1 | 1 to 4294967294 | Set the numerator of the 1st group electronic gear ratio for position instruction frequency division or multiplication. P00-16 is effective when the number of instruction pulses of one motor rotation is 0. ✎Note:The setting range of VD2L is inconsistent with other models in the VD2 series. | - |

| P00-18 | Electronic gear 1 denominator | Operation setting | Effective immediately | 1 | 1 to 4294967294 | Set the denominator of the 1st group electronic gear ratio for position instruction frequency division or multiplication. P00-16 is effective when the number of instruction pulses of one motor rotation is 0. ✎Note:The setting range of VD2L is inconsistent with other models in the VD2 series. | - |

| P00-19 | Electronic gear 2 numerator | Operation setting | Effective immediately | 1 | 1 to 4294967294 | Set the numerator of the 2nd group electronic gear ratio for position instruction frequency division or multiplication. P00-16 is effective when the number of instruction pulses of one motor rotation is 0. ✎Note:The setting range of VD2L is inconsistent with other models in the VD2 series. For:1~2147483647. | - |

| P00-20 | Electronic gear 2 denominator | Operation setting | Effective immediately | 1 | 1 to 4294967294 | Set the denominator of the 2nd group electronic gear ratio for position instruction frequency division or multiplication. P00-16 is effective when the number of instruction pulses of one motor rotation is 0. ✎Note:The setting range of VD2L is inconsistent with other models in the VD2 series. For:1~2147483647. | - |

Table 6-22 Electronic gear ratio function code

To use electronic gear ratio 2, it is necessary to configure any DI port as function 09 (GEAR-SEL electronic gear switch 1), and determine the valid logic of the DI terminal.

| DI function code | Function name | Function |

|---|---|---|

| 09 | GEAR-SEL electronic gear switch 1 | DI port logic invalid: electronic gear ratio 1 DI port logic valid: electronic gear ratio 2 |

Table 6-23. Switching conditions of electronic gear ratio group

| P00-16 value | DI terminal level corresponding to DI port function 9 | Electronic gear ratio |

|---|---|---|

| 0 | DI port logic invalid |

|

| DI port logic valid |

| |

| 1 to 131072 | -- |

|

Table 6-24 Application of electronic gear ratio

When the function code P00-16 is not 0, the electronic gear ratio  is invalid.

is invalid.

Position instruction filtering

Position instruction filtering is to filter the position instruction (encoder unit) after the electronic gear ratio frequency division or frequency multiplication, including first-order low-pass filtering and average filtering operation.

In the following situations, position instruction filtering should be added.

- The position instruction output by host computer has not been processed with acceleration or deceleration;

- The pulse instruction frequency is low;

- When the electronic gear ratio is 10 times or more.

Reasonable setting of the position loop filter time constant can operate the motor more smoothly, so that the motor speed will not overshoot before reaching the stable point. This setting has no effect on the number of instruction pulses. The filter time is not as long as possible. If the filter time is longer, the delay time will be longer too, and the response time will be correspondingly longer. It is an illustration of several kinds of position filtering.

Figure 6-25 Position instruction filtering diagram

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P04-01 | Pulse instruction filtering method | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: 1st-order low-pass filtering 1: average filtering | - |

| P04-02 | Position instruction 1st-order low-pass filtering time constant | Shutdown setting | Effective immediately | 0 | 0 to 1000 | Position instruction first-order low-pass filtering time constant | ms |

| P04-03 | Position instruction average filtering time constant | Shutdown setting | Effective immediately | 0 | 0 to 128 | Position instruction average filtering time constant | ms |

Table 6-25 Position instruction filter function code

Clearance of position deviation

Position deviation clearance means that the drive could zero the deviation register in position mode. The user can realize the function of clearing the position deviation through the DI terminal;

Position deviation = (position instruction-position feedback) (encoder unit)

Position-related DO output function

The feedback value of position instruction is compared with different thresholds, and output DO signal for host computer use.

Positioning completion/positioning approach output

the positioning completion function means that when the position deviation meets the value set by P05-12, it could be considered that the positioning is complete in position control mode. At this time, servo drive could output the positioning completion signal, and the host computer could confirm the completion of the positioning of servo drive after receiving the signal.

Figure 6-26 Positioning completion signal output diagram

When using the positioning completion or approach function, you could also set positioning completion, positioning approach conditions, window and hold time. The principle of window filter time is shown in Figure 6-27.

To use the positioning completion/positioning approach function, a DO terminal of the servo drive should be assigned to the function 134 (P-COIN, positioning completion)/ 135 (P-NEAR, positioning approach). The related code parameters and DO function codes are shown as Table 6-26.

Figure 6-27 Positioning completion signal output with increased window filter time diagram

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-12 | Positioning completion threshold | Operation setting | Effective immediately | 800 | 1 to 65535 | Positioning completion threshold | Equivalent pulse unit |

| P05-13 | Positioning approach threshold | Operation setting | Effective immediately | 5000 | 1 to 65535 | Positioning approach threshold | Equivalent pulse unit |

| P05-14 | Position detection window time | Operation setting | Effective immediately | 10 | 0 to 20000 | Set positioning completion detection window time | ms |

| P05-15 | Positioning signal hold time | Operation setting | Effective immediately | 100 | 0 to 20000 | Set positioning completion output hold time | ms |

Table 6-26 Function code parameters of positioning completion

| DO function code | Function name | Function |

|---|---|---|

| 134 | P-COIN positioning complete | Output this signal indicates the servo drive position is complete. |

| 135 | P-NEAR positioning close | Output this signal indicates that the servo drive position is close. |

Table 6-27 Description of DO rotation detection function code

VD2-0xxSA1H collector pulse signal DO Function and VD2L pulse signal DO output function

(1) VD2-0xxSA1H collector pulse signal DO Function

The pulse signal of VD2-0xxSA1H is a collector signal output through DO, which can be connected to the high-speed pulse input of PLC without conversion through differential to collector circuit board. However, the pulse frequency division output used by VD2 series is a differential signal, which needs to pass through differential to collector circuit board to be connected to the high-speed pulse input of PLC.

(2) Pulse signal DO output function of VD2L-0xxSA1P

The pulse signal of VD2L-0xxSA1P is the collector signal output by DO, and it can be connected to the high-speed pulse input of PLC without the conversion of differential to collector circuit board.

(3) The difference of collector pulse signal DO Function of VD2-0xxSA1H and DO output function of pulse signal of VD2L-0xxSA1P

The pulse signal of VD2-0xxSA1H is the collector signal output through DO, and it is a 4 times frequency pulse signal of Phase A/B. DO signal of VD2L is a pulse+direction signal.

DO2, DO3, and DO4 respectively correspond to the pulse frequency division outputs of the Z-axis, A-axis, and B-axis of the pulse output, as shown in the following table.

| P06-28 | Parameter name | Setting method | Effective time | Default | Set range | Application category | Unit | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DO_2 channel function selection | Operation setting | Effective immediately | 130 | 128-149 | DI/DO | - | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Used to set DO functions corresponding to hardware DO2. Refer to the following table for the functions corresponding to the set value:

When P06-28 is set to a value other than the above table, it is considered to not use DO port function. The same DO channel function is not allowed to be assigned to multiple DO ports, otherwise the servo driver will report A-90 (DO port configuration duplicate). Note 1: To use the BRK-OFF function code, you need to repower to take effect. Note 2: ① Only VD2L and VD2F support function code 143. The code for this function of VD2-0xxSA1G model is empty! ② Only in the VD2-0xxSA1H model, the default function code for the DO_1 channel function selection is 130ALM (fault signal)! In the VD2-0xxSA1H model, the function code for the DO_2, DO_3, and DO_4 channels are 143 OZ (Z/A/B pulse output), and these 3 channels correspond to the Z-axis, A-axis, and B-axis of the pulse output respectively! ③ The function selection code of DO_2, DO_3 and DO_4 channels in the VD2L-0xxSA1P model are 143 OZ (Z pulse output), and these 3 channels correspond to Z axis, pulse axis, and direction axis of the pulse output respectively! ④ VD2L does not support 149 function code at this time. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| P06-30 | Parameter name | Setting method | Effective time | Default | Set range | Application category | Unit | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DO_3 channel function selection | Operation setting | Effective immediately | 129 | 128-149 | DI/DO | - | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Used to set DO functions corresponding to hardware DO3. Refer to the following table for the functions corresponding to the set value:

When P06-30 is set to a value other than the above table, it is considered to not use DO port function. The same DO channel function is not allowed to be assigned to multiple DO ports, otherwise the servo driver will report A-90 (DO port configuration duplicate). Note 1: To use the BRK-OFF function code, you need to repower to take effect. Note 2: ① Only VD2L and VD2F support function code 143. The code for this function of VD2-0xxSA1G model is empty! ② Only in the VD2-0xxSA1H model, the default function code for the DO_1 channel function selection is 130ALM (fault signal)! In the VD2-0xxSA1H model, the function code for the DO_2, DO_3, and DO_4 channels are 143 OZ (Z/A/B pulse output), and these 3 channels correspond to the Z-axis, A-axis, and B-axis of the pulse output respectively! ③ The function selection code of DO_2, DO_3 and DO_4 channels in the VD2L-0xxSA1P model are 143 OZ (Z pulse output), and these 3 channels correspond to Z axis, pulse axis, and direction axis of the pulse output respectively! ④ VD2L does not support 149 function code at this time. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| P06-32 | Parameter name | Setting method | Effective time | Default | Set range | Application category | Unit | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DO_4 channel function selection | Operation setting | Effective immediately | 134 | 128-149 | DI/DO | - | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Used to set DO functions corresponding to hardware DO4. Refer to the following table for the functions corresponding to the set value:

When P06-32 is set to a value other than the above table, it is considered to not use DO port function. The same DO channel function is not allowed to be assigned to multiple DO ports, otherwise the servo drive will report A-90 (DO port configuration duplicate). Note 1: To use the BRK-OFF function code, you need to repower to take effect. Note 2: ① Only VD2L and VD2F support function code 143. The code for this function of VD2-0xxSA1G model is empty! ② Only in the VD2-0xxSA1H model, the default function code for the DO_1 channel function selection is 130ALM (fault signal)! In the VD2-0xxSA1H model, the function code for the DO_2, DO_3, and DO_4 channels are 143 OZ (Z/A/B pulse output), and these 3 channels correspond to the Z-axis, A-axis, and B-axis of the pulse output respectively! ③ The function selection code of DO_2, DO_3 and DO_4 channels in the VD2L-0xxSA1P model are 143 OZ (Z pulse output), and these 3 channels correspond to Z axis, pulse axis, and direction axis of the pulse output respectively! ④ VD2L does not support 149 function code at this time. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Speed control mode

Speed control refers to controlling the speed of the machine through speed instructions. Given the speed instruction by digital voltage or communication, the servo drive can control the mechanical speed fast and precisely. Therefore, the speed control mode is mainly used to control the rotation speed such as analog CNC engraving and milling machine. Figure 6-28 is the speed control block diagram.

Figure 6-28 Speed control block diagram

Speed instruction input setting

In speed control mode, VD2A and VD2B servo drives have two instruction source: internal speed instruction and analog speed instruction. VD2F drive only supports internal speed instruction. Speed instruction source is set by function code P01-01.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-01 | Speed instruction source | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: internal speed instruction 1: AI_1 analog input (not supported by VD2F and VD2L) | - |

Table 6-28 Speed instruction source parameter

Speed instruction source is internal speed instruction (P01-01=0)

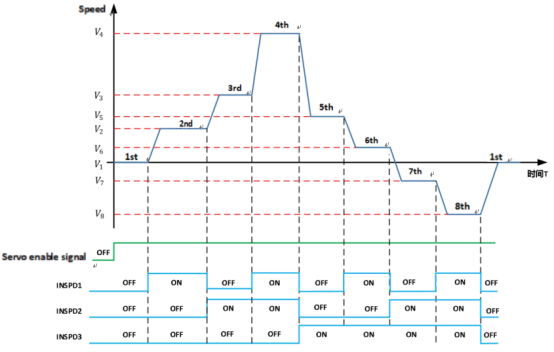

Speed instruction comes from internal instruction, and the internal speed instruction is given by a number. The VD2 series servo drive has internal multi-segment speed running function. There are 8 segments speed instructions stored in servo drive, and the speed of each segment could be set individually. The servo drive uses the 1st segment internal speed by default. To use the 2nd to 8th segment internal speed, the corresponding number of DI terminals must be configured as functions 13, 14, and 15. The detailed parameters and function codes are shown as below.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P01-02 | Internal speed Instruction 0 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 0 When DI input port: 15-INSPD3: 0 14-INSPD2: 0 13-INSPD1: 0, select this speed instruction to be effective. | rpm | |||||||

| P01-23 | Internal speed Instruction 1 | Operation setting | Effective immediately | 0 | --6000 to 6000 | Internal speed instruction 1 When DI input port: 15-INSPD3: 0 14-INSPD2: 0 13-INSPD1: 1, Select this speed instruction to be effective. | rpm | |||||||

| P01-24 | Internal speed Instruction 2 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 2 When DI input port: 15-INSPD3: 0 14-INSPD2: 1 13-INSPD1: 0, Select this speed instruction to be effective. | rpm | |||||||

| P01-25 | Internal speed Instruction 3 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 3 When DI input port: 15-INSPD3: 0 14-INSPD2: 1 13-INSPD1: 1, Select this speed instruction to be effective. | rpm | |||||||

| P01-26 | Internal speed Instruction 4 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 4 When DI input port: 15-INSPD3: 1 14-INSPD2: 0 13-INSPD1: 0, Select this speed instruction to be effective. | rpm | |||||||

| P01-27 | Internal speed Instruction 5 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 5 When DI input port: 15-INSPD3: 1 14-INSPD2: 0 13-INSPD1: 1, Select this speed instruction to be effective. | rpm | |||||||

| P01-28 | Internal speed Instruction 6 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 6 When DI input port: 15-INSPD3: 1 14-INSPD2: 1 13-INSPD1: 0, Select this speed instruction to be effective. | rpm | |||||||

| P01-29 | Internal speed Instruction 7 | Operation setting | Effective immediately | 0 | -6000 to 6000 | Internal speed instruction 7 When DI input port: 15-INSPD3: 1 14-INSPD2: 1 13-INSPD1: 1, Select this speed instruction to be effective. | rpm | |||||||

Table 6-29 Internal speed instruction parameters

| DI function code | function name | Function |

|---|---|---|

| 13 | INSPD1 internal speed instruction selection 1 | Form internal multi-speed running segment number |

| 14 | INSPD2 internal speed instruction selection 2 | Form internal multi-speed running segment number |

| 15 | INSPD3 internal speed instruction selection 3 | Form internal multi-speed running segment number |

Table 6-30 DI multi-speed function code description

The multi-speed segment number is a 3-bit binary number, and the DI terminal logic is level valid. When the input level is valid, the segment selection bit value is 1, otherwise it is 0. The corresponding relationship between INSPD1 to 3 and segment numbers is shown as below.

| INSPD3 | INSPD2 | INSPD1 | Running segment number | Internal speed instruction number |

|---|---|---|---|---|

| 0 | 0 | 0 | 1 | 0 |

| 0 | 0 | 1 | 2 | 1 |

| 0 | 1 | 0 | 3 | 2 |

| ...... | ||||

| 1 | 1 | 1 | 8 | 7 |

Table 6-31 Correspondence between INSPD bits and segment numbers

Figure 6-29 Multi-segment speed running curve

Speed instruction source is internal speed instruction (P01-01=1)

The servo drive processes the analog voltage signal output by the host computer or other equipment as a speed instruction. VD2A and VD2B series servo drives have 2 analog input channels: AI_1 and AI_2. AI_1 is analog speed input, and AI_2 is analog speed limit.

Figure 6-30 Analog input circuit

Taking AI_1 as an example, the method of setting the speed instruction of analog voltage is illustrated as below.

Figure 6-31 Analog voltage speed instruction setting steps

Explanation of related terms:

- Zero drift: When analog input voltage is 0, the servo drive sample voltage value relative to the value of GND.

- Bias: After zero drift correction, the corresponding analog input voltage when the sample voltage is 0.

- Dead zone: It is the corresponding analog input voltage interval when the sample voltage is 0.

Figure 6-32 AI_1 diagram before and after bias

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-01 ★ | AI_1 input bias | Operation setting | Effective immediately | 0 | -5000 to 5000 | Set AI_1 channel analog bias value | mV |

| P05-02 ★ | AI_1 input filter time constant | Operation setting | Effective immediately | 200 | 0 to 60000 | AI_1 channel input first-order low-pass filtering time constant | 0.01ms |

| P05-03 ★ | AI_1 dead zone | Operation setting | Effective immediately | 20 | 0 to 1000 | Set AI_1 channel quantity dead zone value | mV |

| P05-04 ★ | AI_1 zero drift | Operation setting | Effective immediately | 0 | -500 to 500 | Automatic calibration of zero drift inside the drive | mV |

Table 6-32 AI_1 parameter

Acceleration and deceleration time setting

The acceleration and deceleration time setting can achieve the expectation of controlling acceleration by converting the speed instruction with higher acceleration into the speed instruction with gentle acceleration.

In the speed control mode, excessive acceleration of the speed instruction will cause the motor to jump or vibrate. Therefore, a suitable acceleration and deceleration time can realize the smooth speed change of the motor and avoid the occurrence of mechanical damage caused by the above situation.

Figure 6-33 of acceleration and deceleration time diagram

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-03 | Acceleration time | Operation setting | Effective immediately | 50 | 0 to 65535 | The time for the speed instruction to accelerate from 0 to 1000rpm | ms |

| P01-04 | Deceleration time | Operation setting | Effective immediately | 50 | 0 to 65535 | The time for the speed instruction to decelerate from 1000rpm to 0 | ms |

Table 6-33 Acceleration and deceleration time parameters

Speed instruction limit

In speed mode, the servo drive could limit the size of the speed instruction. The sources of speed instruction limit include:

- P01-10: Set the maximum speed limit value

- P01-12: Set forward speed limit value

- P01-13: Set reverse speed limit value

- The maximum speed of the motor: determined by motor model

The actual motor speed limit interval satisfies the following relationship:

The amplitude of forward speed instruction ≤ min (Maximum motor speed, P01-10, P01-12)

The amplitude of negative speed command ≤ min (Maximum motor speed, P01-10, P01-13)

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-10 | Maximum speed threshold | Operation setting | Effective immediately | 3600 | 0 to 8000 | Set the maximum speed limit value, if exceeds this value, an overspeed fault will be reported | rpm |

| P01-12 | Forward speed threshold | Operation setting | Effective immediately | 3000 | 0 to 6000 | Set forward speed limit value | rpm |

| P01-13 | Reverse speed threshold | Operation setting | Effective immediately | 3000 | 0 to 6000 | Set reverse speed limit value | rpm |

Table 6-34 Rotation speed related function codes

Zero-speed clamp function

The zero speed clamp function refers to the speed control mode, when the zero speed clamp signal (ZCLAMP) is valid, and the absolute value of the speed instruction is lower than the zero speed clamp speed threshold (P01-22), the servo motor is at In locked state, the servo drive is in position lock mode at this time, and the speed instruction is invalid.

If the speed instruction amplitude is greater than zero-speed clamp speed threshold, the servo motor exits the locked state and continues to run according to the current input speed instruction.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-21 | Zero-speed clamp function selection | Operation setting | Effective immediately | 0 | 0 to 3 | Set the zero-speed clamp function. In speed mode: 0: Force the speed to 0; 1: Force the speed to 0, and keep the position locked when the actual speed is less than P01-22 2: When speed instruction is less than P01-22, force the speed to 0 and keep the position locked 3: Invalid, ignore zero-speed clamp input | - |

| P01-22 | Zero-speed clamp speed threshold | Operation setting | Effective immediately | 20 | 0 to 1000 | Set the speed threshold of zero-speed clamp function | rpm |

Table 6-35 Zero-speed clamp related parameters

Figure 6-34 Zero-speed clamp diagram

Speed-related DO output function

The feedback value of the position instruction is compared with different thresholds, and could output DO signal for host computer use.

Rotation detection signal

After the speed instruction is filtered, the absolute value of the actual speed absolute value of the servo motor reaches P05-16 (rotation detection speed threshold), it could be considered that the motor is rotating. At this time, the servo drive outputs a rotation detection signal (TGON), which can be used to confirm that the motor has rotated. On the contrary, when the absolute value of the actual rotation speed of the servo motor is less than P05-16, it is considered that the motor is not rotating.

Figure 6-35 Rotation detection signal diagram

To use the motor rotation detection signal output function, a DO terminal of the servo drive should be assigned to function 132 (T-COIN, rotation detection). The function code parameters and related DO function codes are shown in Table 6-36and Table 6-37.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-16 | Rotation detection speed threshold | Operation setting | Effective immediately | 20 | 0 to 1000 | Set the motor rotation signal judgment threshold | rpm |

Table 6-36 Rotation detection speed threshold parameters

| DO function code | Function name | Function |

|---|---|---|

| 132 | T-GON rotation detection | Valid: when the absolute value of motor speed after filtering is greater than or equal to the set value of function code P05-16 Invalid, when the absolute value of motor speed after filtering is less than set value of function code P05-16 |

Table 6-37 DO rotation detection function code

Zero-speed signal

If the absolute value of the actual speed of servo motor is less than a certain threshold P05-19, it is considered that servo motor stops rotating (close to a standstill), and the servo drive outputs a zero speed signal (ZSP) at this time. On the contrary, if the absolute value of the actual speed of the servo motor is not less than this value, it is considered that the motor is not at a standstill and the zero-speed signal is invalid.

Figure 6-36 Zero-speed signal diagram

To use the motor zero-speed signal output function, a DO terminal of servo drive should be assigned to function 133 (ZSP, zero-speed signal). The function code parameters and related DO function codes are shown in Table 6-38 and Table 6-39.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-19 | Zero speed output signal threshold | Operation setting | Effective immediately | 10 | 0 to 6000 | Set zero-speed output signal judgment threshold | rpm |

Table 6-38 Zero-speed output signal threshold parameter

| DO function code | Function name | Function |

|---|---|---|

| 133 | ZSP zero speed signal | Output this signal indicates that the servo motor is stopping rotation |

Table 6-39 DO zero-speed signal function code

Speed consistent signal

When the absolute value of the deviation between the actual speed of the servo motor after filtering and the speed instruction meets a certain threshold P05-17, it is considered that the actual speed of the motor has reached the set value, and the servo drive outputs a speed coincidence signal (V-COIN) at this time. Conversely, if the absolute value of the deviation between the actual speed of the servo motor and the set speed instruction after filtering exceeds the threshold, the speed consistent signal is invalid.

Figure 6-37 Speed consistent signal diagram

To use the motor speed consistent function, a DO terminal of the servo drive should be assigned to function 136 (V-COIN, consistent speed). The function code parameters and related DO function codes are shown in Table 6-40and Table 6-41.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-17 | Speed consistent signal threshold | Operation setting | Effective immediately | 10 | 0 to 100 | Set speed consistent signal threshold | rpm |

Table 6-40 Speed consistent signal threshold parameters

| DO Function code | Function name | Function |

|---|---|---|

| 136 | V-COIN consistent speed | The output signal indicates that the absolute deviation of the actual speed of servo motor and the speed instruction meets the P05-17 set value |

Table 6-41 DO speed consistent function code

Speed approach signal

After filtering, the absolute value of the actual speed of the servo motor exceeds a certain threshold [P05-17], and it is considered that the actual speed of the servo motor has reached the expected value. At this time, the servo drive can output a speed close signal (V-NEAR) through the DO terminal. Conversely, if the absolute value of the actual speed of the servo motor after filtering is not greater than this value, the speed approach signal is invalid.

Figure 6-38 Speed approaching signal diagram

To use the motor speed approach function, a DO terminal of the servo drive should be assigned to function 137 (V-NEAR, speed approach). The function code parameters and related DO function codes are shown in Table 6-42 and Table 6-43

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-18 | Speed approach signal threshold | Operation setting | Effective immediately | 100 | 10 to 6000 | Set speed approach signal threshold | rpm |

Table 6-42 Speed approaching signal threshold parameters

| DO function code | Function name | Function |

|---|---|---|

| 137 | V-NEAR speed approach | The output signal indicates that the actual speed of the servo motor has reached the expected value |

Table 6-43 DO speed approach function code

Torque control mode

The current of the servo motor has a cablear relationship with the torque. Therefore, the control of the current can realize the control of the torque. Torque control refers to controlling the output torque of the motor through torque instructions. Torque instruction could be given by internal instruction and analog voltage.

Figure 6-39 Torque mode diagram

Torque instruction input setting

In torque instruction, VD2A and VD2B servo drives have two instruction source: internal torque instruction and analog torque instruction. VD2F and VD2L drive only has internal torque instruction. The torque instruction source is set by the function code P01-07.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-07 | Torque instruction source | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: internal torque instruction 1: AI_1 analog input(not supported by VD2F and VD2L) | - |

Table 6-44 Torque instruction source parameter

Torque instruction source is internal torque instruction (P01-07=0)

Torque instruction source is from inside, the value is set by function code P01-08.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-08 | Torque instruction keyboard set value | Operation setting | Effective immediately | 0 | -3000 to 3000 | -300.0% to 300.0% | 0.1% |

Table 6-45 Torque instruction keyboard set value

Torque instruction source is AI_1 analog input (P01-07=1)

The servo drive processes the analog voltage signal output by host computer or other equipment as torque instruction. VD2A and VD2B series servo drives have 2 analog input channels: AI_1 and AI_2. AI_1 is analog torque input, and AI_2 is analog torque limit.

Figure 6-40 Analog input circuit

Taking AI_1 as an example, the method of setting torque instruction of analog voltage is as below.

Figure 6-41 Analog voltage torque instruction setting steps

Explanation of related terms:

- Zero drift: When analog input voltage is 0, the servo drive sample voltage value relative to the value of GND.

- Bias: After zero drift correction, the corresponding analog input voltage when the sample voltage is 0.

- Dead zone: It is the corresponding analog input voltage interval when the sample voltage is 0.

Figure 6-42 AI_1 diagram before and after bias

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P05-01☆ | AI_1 input bias | Operation setting | Effective immediately | 0 | -5000 to 5000 | Set AI_1 channel analog bias value | mV |

| P05-02☆ | AI_1 input filter time constant | Operation setting | Effective immediately | 200 | 0 to 60000 | AI_1 channel input first-order low-pass filtering time constant | 0.01ms |

| P05-03☆ | AI_1 dead zone | Operation setting | Effective immediately | 20 | 0 to 1000 | Set AI_1 channel dead zone value | mV |

| P05-04☆ | AI_1 zero drift | Operation setting | Effective immediately | 0 | -500 to 500 | Automatic calibration of zero drift inside the drive | mV |

Table 6-46 AI_1 parameters

Torque instruction filtering

In torque mode, the servo drive could realize low-pass filtering of torque instruction, making the instruction smoother and reducing the vibration of servo motor. The first-order filtering is shown in Figure 6-43.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P04-04 | Torque filtering time constant | Operation setting | Effective immediately | 50 | 10 to 2500 | This parameter is automatically set when “self-adjustment mode selection” is selected as 0 | 0.01ms |

Table 6-47 Torque filtering time constant parameter details

Figure 6-43 Torque instruction-first-order filtering diagram

Torque instruction limit

When the absolute value of torque instruction input by host computer is greater than the absolute value of torque instruction limit, the drive's actual torque instruction is limited and equal to the limit value of torque instruction. Otherwise, it is equal to the torque instruction value input by host computer.

At any time, there is only one valid torque limit value. And the positive and negative torque limit values do not exceed the maximum torque of drive and motor and ±300.0% of the rated torque.

Figure 6-44 Torque instruction limit diagram

Set torque limit source

You need to set the torque limit source by function code P01-14. After the setting, the drive torque instruction will be limited within the torque limit value. When the torque limit value is reached, the motor will operate with the torque limit value as the torque instruction. The torque limit value should be set according to the load operation requirements. If the setting is too small, the motor's acceleration and deceleration capacity may be weakened. During constant torque operation, the actual motor speed cannot reach the required value.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-14 | Torque limit source | Shutdown setting | Effective immediately | 0 | 0 to 1 | 0: internal value 1: AI_1 analog input (not supported by VD2F and VD2L) | - |

- Torque limit source is internal torque instruction (P01-14=0)

Torque limit source is from inside, you need to set torque limit, and the value is set by function code P01-15 and P01-16.

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|

| P01-15 | Forward torque limit | Operation setting | Effective immediately | 3000 | 0 to 3000 | When P01-14 is set to 0, the value of this function code is forward torque limit value | 0.1% |

| P01-16 | Reverse torque limit | Operation setting | Effective immediately | 3000 | 0 to 3000 | When P01-14 is set to 0, the value of this function code is reverse torque limit value | 0.1% |

Table 6-48 Torque limit parameter details

- Torque limit source is external (P01-14=1)

Torque limit source is from external analog channel. The limit value is determined by the torque value corresponding to external AI_2 terminal.

Set torque limit DO signal output

When torque instruction reaches the torque limit value, the drive outputs a torque limit signal (T-LIMIT) for the host computer use. At this time, one DO terminal of the drive should be assigned to function 139 (T-LIMIT, in torque limit) , and confirm that the terminal logic is valid.

| DO function code | Function name | Function |

|---|---|---|

| 139 | T-LIMIT in torque limit | Output of this signal indicates that the servo motor torque is limited |

Table 6-49 DO torque limit function codes

Speed limit in torque mode

In torque mode, if the given torque instruction is too large to exceed the load torque of the mechanical side. This would cause the servo motor to continuously accelerate and overspeed. In order to protect the machinery, the speed of the motor must be limited.

In torque mode, the actual motor speed would be in the limited speed. After the speed limit is reached, the motor runs at a constant speed at the speed limit. The running curves are shown as Figure 6-45 and Figure 6-46.

Figure 6-45 Forward running curve |  Figure 6-46 Reverse running curve |

| Function code | Name | Setting method | Effective time | Default value | Range | Definition | Unit |

|---|---|---|---|---|---|---|---|