12 PLC Protocol OLD

Introduction

This chapter contains information on configuring the communication between device and HMI.

General Procedure

During configuring communication in PIStudio. The following components and conditions is indeed at least.

- One PI HMI

- One connected controller (for example PLC)

- One Cable Wiring

User need to select controller protocol and set communication parameters in HMI project. Please note to set same communication parameter between controller and HMI project. After finishing project, user could download HMI project into HMI and connect HMI with controller by Cable Wiring. Thena simple automation system would be established.

Communication Settings

For example, controller is WECON LX3V series PLC and HMI is PI8070. Please set communication protocol, and set communication parameters in the [Communication].

Timeout

The follwoing are description for the timeout settings from [Communication].

- Wait Timeout(ms): The time HMI waits for a response from the PLC.

- Receive Timeout(ms): The longest waiting interval between the HMI receiving two characters.

- Retry Count: The number of retries when there is no response in the communication between HMI and PLC.

- Retry Timeout(s): The PLC will not be accessed during the Retry Timeout period when there is no response in the communication between HMI and PLC.

- Delay Time(ms): The speed at which the HMI communicates with the device.

- Continuous Length: Default value 0 means the maximum length specified by each protocol. Addresses dealt by Maximum Span settings, its read length for single time, if the Continouous Length is 1, which means it will read/write the every register one by one. If the length of Maximum Span is greater than or equal to the Continuous Length, the continuous read/write will be performed in groups according to Continuous Length.

- Maximum Span: Set the interval for reading PLC addresses. If there exists two same register type addresses, their interval is less than the set value of Maximum Span, then they will be integrated into a continuous address, otherwise it will be divide into two independent addresses.

Operating Procedure

After creating the [Quick_Start] project,select the [Project]->[Communication].

Click “Setting” to open protocol setting windows.

Select communication protocol, users could select serial port, Ethernet port, CAN port or USB.

- Serial port:

- Ethernet port:

- CAN port (In COM1):

- USB port:

About parameters for communication, PLC default communication parameters have been written to PIStudio, the user can adjust them according to the actual situation.

- Serial port:

- Ethernet port

Please note, during using Ethernet port, please set HMI IP in [Project Setting], the detailed, please refer to [Project Setting] chapter.

Click [OK] button to save settings and close the dialog;

Limitation for Ethernet communication protocol

The table below shows the maximum number of communications configured for the general protocol,Free Tag Protocol and CodeSys V3 Protocol on each series model.

(Only HMI V2.0 System supports Free Tag Protocol and CodeSys V3 Protocol)

| HMI Series | General Protocol | FreeTags Protocol | CodeSys V3 Protocol |

|---|---|---|---|

| General 3000 Series | 16 | N/A | N/A |

| General 8000 Series | 24 | 4 | N/A |

| General 9000 Series | 32 | N/A | N/A |

| PI3000i Series | 16 | N/A | N/A |

| PI3000ie Series (PI3043ieS-N) | 16 | 2 | N/A |

| PI3000ie Series (other model) | N/A | N/A | N/A |

| PI3000ig Series (PI3070ig-O & PI3102ig-O) | 16 | N/A | N/A |

| PI3000ig Series (other model) | 16 | 4 | 2 |

| PI8000ig Series | 32 | 6 | 2 |

WECON

LX3 Series

Supported series: WECON LX2V/ LX2E/ LX3V/LX3VP/LX3VE/LX3VM

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | WECON LX2V/ LX2E/ LX3V/LX3VP/LX3VE/LX3VM | |

| Connection | RS422/RS485 | |

| Baud rate | 9600 | |

| Data bit | 7 | |

| Parity | EVEN | |

| Stop bit | 1 | |

| PLC station No. | 1 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | Xo | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~99999 | ||

| S | S | S d | 0~99999 | ||

| Word | X | X | Xo | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~199 | ||

| D | D | D d | 0~7999 | ||

| S | S | S d | 0~99999 | ||

| SD | SD | SD d | 8000~9999 |

Cable Wiring

- RS485

- RS422

HMI settings

Download PIStudio Software

Please visit the link below to get the latest version PIstudio for HMI programming:

Create a new HMI project connect with PLC

Check the link below for the video to show you how to get started with a new project

For more videos, please visit our Youtube channel: http://www.youtube.com/user/Wecon2004/videos

General

HMI could communicate with PLC and support many PLC protocols. It is easy to operate and set communication parameters. This demo shows how to make a communication with PLC device, use WECON LX3V Series PLC as an example.

Protocol settings

The communication between two devices requires a protocol. The following contents show the steps of protocol settings.

Please select the protocol, when creating a new project.

- Select the COM port for communication;

- PLC type: It means PLC brand, like WECON;

- PLC model: It shows the model of PLC, such as LX3V;

If you want to change the protocol for existing project, please click [Project] → [Communication] to open the [Communication] windows, shown as the following figure.

The steps to change the protocol for project are as follows.

- Click [Setting] to open the [Communication device] window;

- Select communication port, such as COM1;

- Select Serial port for communication, such as RS422;

- Select device type (device brand), such as WECON;

- Select the protocol for communication, such as WECON LX3V;

Parameter settings

The parameters settings are in [Communication] window, shown as following below.

- Click [Setting] to open the [COM port setting] window;

- Set the parameters such as [connection], [Baud rate] and so on;

- Click [Setting] to open [Timeout] setting window, you could set the parameters according your requirements, or just use the default value.

Set PLC address in HMI screen

- Place the objects to HMI screen;

- Double-click the object to open the setting window;

- Click “Edit” to open the address setting windows;

- Connection: select the serial port in HMI;

- Address type: All the PLC address types will be display in this list, such as M;

- Address No.: Please input the number of this address, such as 0;

HMI Compilation Download

Communication cable

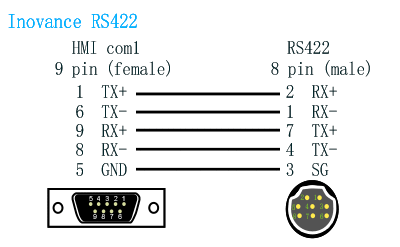

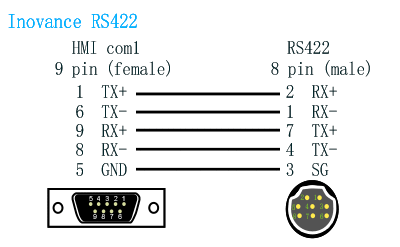

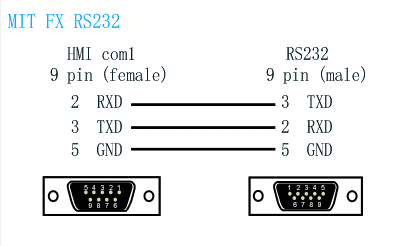

In order to ensure the stability of communication, please use the twisted-pair communication cable with good grounding. The following figure shows the pin out definition.

HMI communication PLC use Modbus

- HMI setting: https://docs.we-con.com.cn/bin/view/PIStudio/12.PLC%20protocols/

- PLC setting: https://docs.we-con.com.cn/bin/view/PLC%20Editor/8.1.%09Communication/

PLC settings

Download PLC Software

Please visit below link to get the latest version PLC Editor for HMI programming

- LX3V:Download link

- LX5V:Download link

Start a new PLC project

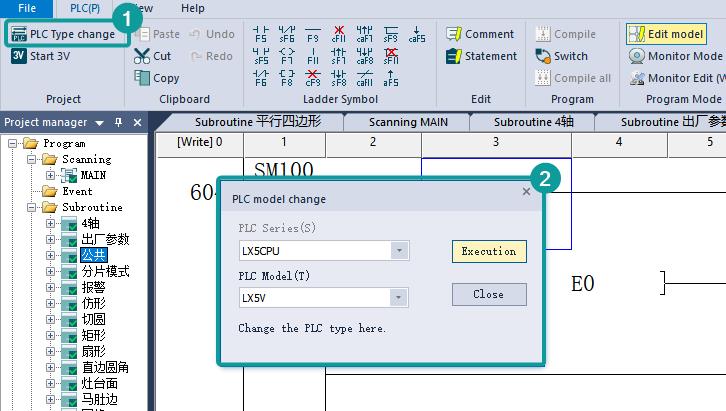

Start a new PLC project by clicking “New” on the left top corner of screen, select the PLC mode from the drop-down list.

Add a new instruction

Double click on the ladder, select the ladder symbol (instruction) from the drop-down list, then enter the address for this symbol.

You could also select the ladder symbol from the menu bar directly.

Add comment to PLC program

Add the statement to PLC program

Add the statement by single click on “Statement”, when finished, single click on “Statement” again to go back to Ladder edit.

Compile

You need to compile the PLC program before downloading or running Off-line simulator. The background color will be changed from purple to white when there is no error.

Download setting

Click on “Transfer Setup” to select download mode.

Download PLC program to PLC

Download PLC program to PLC

Quick select the parameters and main program of PLC program, then download to PLC, “Yes”-”Yes”-”OK”

Upload PLC program from PLC

Read the PLC program from PLC to computer.

Device monitor

Monitor the value of certain address in PLC, double click “Current value” to change the value in this address.

Online monitor

Monitor the each address in PLC by online monitor. Changing the state or value in PLC is also allowd.

Monitor edit

In this mode, you could edit the PLC program during PLC is running.

LX5V Series

This example introduces the establishment of serial port communication between Wecon HMI and LX5V, including three parts: PLC software configuration, HMI software configuration, and hardware wiring.

Software configuration of PLC

PLC programming software

New PLC project

Click "New Project" and select the PLC model.

Set Serial port parameters

Follow the steps below to configure Serial port parameters.

- Baud rate:115200

- Data bit:8

- Stop bit:1

- Parity:No verification

Registers list

HMI software configuration

HMI programming software

New HMI project

Click New Project and select the HMI model.

Set communication port parameters

Click the communication configuration button on the left to find the communication protocol with LX5V. After selecting the protocol, configure the communication parameters of the COM port.

- Baud rate:115200

- Data bit:8

- Stop bit:1

- Parity:No verification

hardware connection

Hardware wiring diagram

This example introduces WeconHMI with LX5V PLC to establish communication through serial port. The connection diagram is as follows:

The above are all the steps for establishing serial port communication between Wecon HMI with LX5V PLC.

LX5V-N Ethernet

This example introduces the establishment of Ethernet communication between Wecon HMI and LX5V, including three parts: PLC software configuration, HMI software configuration, and hardware wiring.

Software configuration of PLC

PLC programming software

New PLC project

Click New Project and select the PLC model.

Set Ethernet port parameters

Follow the steps below to configure Ethernet parameters

- PLC IP address:192.168.39.200

- default gateway:192.168.39.1

- subnet mask:255.255.255.0

Registers list

HMI software configuration

HMI programming software

New HMI project

Click New Project and select the HMI model.

Set communication port parameters

Click the project setting button on the left to configure the IP address of the HMI machine to ensure that the HMI and PLC IP remain in a local area network.

- HMI IP address:192.168.39.201

- Default gateway:192.168.39.1

- Subnet mask:255.255.255.0

Next, click Communication Settings to configure the IP of the HMI communication object.

Hardware connection

This example introduces WeconHMI with LX5V-N PLC to establish communication through ethernet. The connection diagram is as follows:

The above are all the steps for establishing ethernet communication between Wecon HMI with LX5V PLC.

ABB

AC500

Support Series: ABB AC500

HMI Settings

| Item | Recommended | Note |

|---|---|---|

| Protocol | ABB AC500 | |

| Connection | RS232 | |

| Baud rate | 19200 | |

| Stop bits | 1 | |

| Data bits | 8 | |

| Parity | EVEN | |

| PLC Station No. | 1 | |

| HMI Station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | MX | MXdddd.oo | 0.0~8191.7 | |

| Word | MW0 | MW0ddddd | 0~32767 | |

| MW1 | MW1ddddd | 0~32767 |

Cable Wiring

Abzil

Abzil CPL Protocol

Supported series: SDC series

HMI Settings

| Item | Settings | Note |

| Protocol | Abzil CPL | |

| Connection | RS485 | |

| Baud rate | 9600 | |

| Data bit | 8 | |

| Parity | EVEN | |

| Stop bit | 1 | |

| PLC station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

| Bit | 00 | 00DDDD.h | 0~9999.f | |

| 01 | 01DDDD.h | 0~9999.f | ||

| 02 | 02DDDD.h | 0~9999.f | ||

| 03 | 03DDDD.h | 0~9999.f | ||

| 04 | 04DDDD.h | 0~9999.f | ||

| 05 | 05DDDD.h | 0~9999.f | ||

| 06 | 06DDDD.h | 0~9999.f | ||

| 07 | 07DDDD.h | 0~9999.f | ||

| 08 | 08DDDD.h | 0~9999.f | ||

| Word | 00 | 00DDDD | 0~9999 | |

| 01 | 01DDDD | 0~9999 | ||

| 02 | 02DDDD | 0~9999 | ||

| 03 | 03DDDD | 0~9999 | ||

| 04 | 04DDDD | 0~9999 | ||

| 05 | 05DDDD | 0~9999 | ||

| 06 | 06DDDD | 0~9999 | ||

| 07 | 07DDDD | 0~9999 | ||

| 08 | 08DDDD | 0~9999 |

Cable Wiring

Crouzet

M3 (FBD)

Support Series: Crouzet Millenium 3 CD12/CB12

HMI Settings

| Item | Recommended | Note |

|---|---|---|

| Protocol | CROUZET M3 (FBD) | |

| Connection | RS232 | |

| Baud rate | 115200 | |

| Stop bits | 1 | |

| Data bits | 7 | |

| Parity | EVEN | |

| PLC Station No. | 1 | |

| HMI Station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | I | I DD | 1~99 | Input |

| SLIBit | SLIBit DD.dd | 1.0~24.15 | Serial Link Input | |

| SLOBit | SLOBit DD.dd | 25.0~48.15 | Serial Link Output(Read only) | |

| State | State D | 1~1 | PLC state(Read only) | |

| Word | AI | AI DD | 1~99 | Analog Input |

| SLIn | SLIn DD | 1~24 | Serial Link Input | |

| SLOut | SLOut DD | 25~48 | Serial Link Output(Read only) | |

| Time | Time D | 1~6 | Time1: Second Time2: Minute Time3: Hour Time4: Day Time5: Month Time6: Year | |

| Order | Order D | 1~1 | Running command(Write only) =2: Run mode; =1: Stop mode; |

Cable Wiring

Danfoss

FC Series

Support Series: VLT FC300 Drive

HMI Settings

| Item | Recommended |

|---|---|

| Protocol | Danfoss FC Series |

| Connection | RS485 |

| Baud rate | 9600 |

| Stop bits | 1 |

| Data bits | 8 |

| Parity | EVEN |

| PLC Station No. | 1 |

| HMI Station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Word | P | P dddd | 0~4095 | |

| E | E dddd | 0~4095 | ||

| S | S d | 0~1 | ||

| C | C d | 0~1 |

Cable Wiring

Delta

DVP Series

Supported Series: Delta DVP EH/ES/SS/EX/EH2/SV/SA/SC/SX Controller

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | DELTA DVP Series | |

| Connection | RS485 | |

| Baud rate | 9600 | |

| Data bit | 7 | |

| Parity | Even | |

| Stop bit | 1 | |

| PLC station No. | 1~255 | Need to be the same as PLC settings |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | X d | 0~303237 | |

| Bit | Y | Y | Y d | 0~303237 | |

| Bit | M | M | M d | 0~99999 | |

| Bit | T | T | T d | 0~99999 | |

| Bit | C | C | T d | 0~99999 | |

| Bit | S | S | T d | 0~99999 | |

| Word | D | D | D d | 0~99999 | |

| Word | T | T | T d | 0~99999 | |

| Word | C | C | C d | 0~99999 |

Configure the communication protocol

Cable Wiring

DVP Modbus TCP

Supported Series: Delta DVP ES2/EX2/SS2/SA2/SX2/SE Controller

HMI Settings

| Items | Settings | Note |

|---|---|---|

| Protocol | DELTA DVP Modbus TCP | |

| Connection | Ethernet | |

| Port No. | 201 | Must be the same as the PLC setting |

| PLC station No. | 0 | Must be the same as the PLC setting |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | X o | 0~377 | |

| Bit | Y | Y | Y o | 0~377 | |

| Bit | M0 | M0 | M0 d | 0~1535 | |

| Bit | M1 | M1 | M1 d | 1536~4095 | |

| Bit | T | T | T d | 0~255 | |

| Bit | C | C | C d | 0~255 | |

| Bit | S | S | S d | 0~1023 | |

| Word | D0 | D0 | D0 d | 0~4095 | |

| Word | D1 | D1 | D1 d | 4096~11999 |

|

| Word | T | T | T d | 0~255 | |

| Word | C | C | C d | 0~199 |

|

Configure the communication protocol

Cable Wiring

AS300 MODBUS RTU

Supported Series: Delta AS200/AS300

HMI Settings

| Item | Settings | Note |

| Protocol | DELTA AS300 MODBUS RTU | |

| Connection | RS485 | |

| Baud rate | 9600 | |

| Data bit | 8 | |

| Parity | NONE | |

| Stop bit | 1 | |

| PLC station No. | 1 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | Xdd.dd | 0~63.15 | Read only |

| Bit | Y | Y | Ydd.dd | 0~63.15 | |

| Bit | D | D | Dddddd | 0~29999 | |

| Bit | M | M | Mdddd | 0~8191 | |

| Bit | SM | SM | SMdddd | 0~4095 | |

| Bit | S | S | Sdddd | 0~2047 | |

| Bit | T | T | Tddd | 0~511 | |

| Bit | C | C | Cddd | 0~511 | |

| Bit | HC | HC | HCddd | 0~255 | Double Word |

| Word | X | X | Xdd | 0~63 | |

| Word | Y | Y | Ydd | 0~63 | |

| Word | SR | SR | SRdddd | 0~2047 | Special register |

| Word | D | D | Dddddd | 0~29999 | |

| Word | T | T | Tddd | 0~511 | |

| Word | C | C | Cddd | 0~511 | |

| Word | E | E | Ed | 0~9 |

Configure the communication protocol

Create project

Open the tool COMMGR, to communicate with PLC, if know the IP, we can directly click Add to input PLC IP. Or search the PLC IP from LAN.

Double click the HWCONFIG to open the communication settings window.

Expand the Project Tree, open the hardware configuration, double click the PLC icon.

![]()

Click COM1 Port Setting, the default Modbus mode is ASCII, need to change to RTU.

Click Ethernet Port Basic Setting, set the PLC IP and Gateway. Make sure the IP and Gateway is same segment. Then download into PLC.

Cable Wiring

Pin Definition Diagram

AS300 MODBUS TCP

HMI Settings

| Items | Settings | Note |

|---|---|---|

| Protocol | DELTA AS300 MODBUS TCP | |

| Connection | Ethernet | |

| Port No. | 502 | |

| Device No. | 1 | |

| HMI No. | 0 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | X d | 0~63 | |

| Bit | Y | Y | Y d | 0~63 | |

| Bit | D | D | D d | 0~29999 | |

| Bit | M | M | M d | 0~8191 | |

| Bit | SM | SM | SM d | 0~4095 | |

| Bit | S | S | S h | 0~2047 | |

| Bit | T | T | T d | 0~511 | |

| Bit | C | C | C d | 0~511 | |

| Bit | HC | HC | HC d | 0~255 | |

| Word | X | X | X h | 0~63 | |

| Word | Y | Y | Y d | 0~63 | |

| Word | SR | SR | SR d | 0~2047 | |

| Word | D | D | D d | 0~29999 | |

| Word | T | T | T d | 0~511 | |

| Word | C | C | C h | 0~511 | |

| Word | E | E | E d | 0~9 |

Configure the communication protocol

Cable Wiring

EMERSON

RTU Slave Protocol

Supported series: EC10 series

HMI Settings

| Item | Settings | Note |

| Protocol | Emerson 984 RTU Slave MODBUS | |

| Connection | RS485 | |

| Baud rate | 19200 | |

| Data bit | 8 | |

| Parity | EVEN | |

| Stop bit | 1 | |

| PLC station No. | 1 |

PLC Settings

Remember to use the Control Star to enable the Modbus RTU communication for port 1 in system block before dowload into PLC.

Address List

| Type | Device registers | Format | Range | Note |

| Bit | Y | YOOO | 0~377 | |

| X | XOOO | 0~377 | ||

| M0 | M0DDDD | 0~2047 | ||

| M1 | M1DDDDD | 2048~10239 | ||

| SM0 | SM0DDD | 0~255 | ||

| SM1 | SM1DDD | 256~511 | ||

| S0 | S0DDDD | 0~1023 | ||

| S1 | S1DDDD | 1024~4095 | ||

| T0 | T0DDD | 0~255 | ||

| T1 | T1DDD | 256~511 | ||

| C0 | C0DDD | 0~255 | ||

| C1 | C1DDD | 256~306 | ||

| Word | D | DDDDD | 0~7999 | |

| Z | ZDD | 0~15 | ||

| TW0 | TW0DDD | 0~255 | ||

| TW1 | TW1DDD | 256~511 | ||

| SD0 | SD0DDD | 0~255 | ||

| SD1 | SD1DDD | 256~511 | ||

| CW | CWDDD | 0~306 | ||

| Double Word | CW0 | CW0DDD | 200~255 | |

| CW1 | CW1DDDDD | 256~99999 |

Cable Wiring

HollySys

LK MODBUS RTU

Supported Series: HollySys LK series CPU

HMI Settings

| Item | Recommended | Note |

|---|---|---|

| Protocol | HollySys LK MODBUS RTU | |

| Connection | RS485 | |

| Baud rate | 38400 | |

| Stop bits | 1 | |

| Data bits | 8 | |

| Parity | NONE | |

| PLC Station No. | 1 | |

| HMI Station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | QX | QXDDDDD.dd | 0~65535.15 | |

| Bit | IX | IXDDDDD.dd | 0~65535.15 | |

| Bit | MX | MXDDDDD.dd | 0~65535.15 | |

| Word | QW | QWDDDDD | 0~99999 | |

| Word | IW | IWDDDDD | 0~99999 | |

| Word | MW | MWDDDDD | 0~99999 | |

| Word | MD | MDDDDDD | 0~99999 |

Cable Wiring

LM MODBUS RTU

Supported Series: HollySys LM3109/LM3107 PLC

HMI Settings

| Item | Recommended | Optional | Note |

|---|---|---|---|

| Protocol | HollySys LM MODBUS RTU | HollySys LM MODBUS RTU | |

| Connection | RS232 | RS485 | |

| Baud rate | 38400 | 38400 | |

| Stop bits | 1 | 1 | |

| Data bits | 8 | 8 | |

| Parity | NONE | NONE | |

| PLC Station No. | 51 | 51 | |

| HMI Station No. | 0 | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | QX | QXDDDDD.oo | 0~65535.7 | |

| Bit | IX | IXDDDDD.oo | 0~65535.7 | |

| Bit | MX | MXDDDDD.oo | 0~65535.7 | |

| Word | QW | QWDDDDD | 0~99999 | |

| Word | IW | IWDDDDD | 0~99999 | |

| Word | MW | MWDDDDD | 0~99999 | |

| Word | MD | MDDDDDD | 0~99999 |

Cable Wiring

RS232

RS485

Inovance

H1U/H2U Serial

HMI Settings

| Item | Recommended | Note |

|---|---|---|

| Protocol | INOVANCE H1U PLC/INOVANCE H2U PLC | |

| Connection | RS422 | |

| Baud rate | 9600 | |

| Stop bits | 1 | |

| Data bits | 7 | |

| Parity | EVEN | |

| PLC Station No. | 1 | |

| HMI Station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | X | XOOOOOO | 0~303237 | Input Bit |

| Bit | Y | YOOOOOO | 0~303237 | Output Bit |

| Bit | M | MDDDDD | 0~99999 | Auxiliary |

| Bit | T | TDDDDD | 0~99999 | Timer |

| Bit | C | CDDDDD | 0~99999 | Counter |

| Bit | SM | SMDDDD | 8000~9999 | Special Auxiliary |

| Bit | S | SDDDDD | 0~99999 | |

| Bit | Lamp | Lamp0 | 0~0 | Communication Indicator |

| Word | X | X OOOOOO | 0~303237 | Input Word |

| Word | Y | Y OOOOOO | 0~303237 | Output Word |

| Word | M | M DDDDD | 0~99999 | Auxiliary |

| Word | T | T DDDDD | 0~99999 | Timer |

| Word | C | C DDD | 0~199 | Counter |

| Word | D | D DDDD | 0~7999 | Data Register |

| Word | S | S DDDDD | 0~99999 | |

| Word | SD | SD DDDD | 8000~9999 | Special Data Register |

| Double Word | CH | CH DDD | 200~255 |

Cable Wiring

H3U Serial

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | INOVANCE H3U PLC | |

| Connection | RS422 | |

| Baud rate | 9600 | |

| Data bit | 7 | |

| Parity | EVEN | |

| Stop bit | 1 | |

| PLC station No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | X | X OOOOOO | 0~303237 | |

| Bit | Y | Y OOOOOO | 0~303237 | |

| Bit | M | M DDDDD | 0~99999 | |

| Bit | T | T DDDDD | 0~99999 | |

| Bit | C | C DDDDD | 0~99999 | |

| Bit | SM | SM DDDD | 8000~9999 | |

| Bit | S | S DDDDD | 0~99999 | |

| Bit | Lamp | Lamp0 | 0~0 | |

| Word | X | X OOOOOO | 0~303237 | |

| Word | Y | Y OOOOOO | 0~303237 | |

| Word | M | M DDDDD | 0~99999 | |

| Word | T | T DDDDD | 0~99999 | |

| Word | C | C DDD | 0~199 | |

| Word | D | D DDDD | 0~7999 | |

| Word | S | S DDDDD | 0~99999 | |

| Word | SD | SD DDDD | 8000~9999 | |

| Word | R | R DDDDD | 0~32767 | |

| Double Word | CH | CH DDD | 200~255 |

Configure the communication protocol

Cable Wiring

H3U Ethernet

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | INOVANCE H3U PLC Ethernet | |

| Connection | Ethernet | |

| Port No. | 502 | |

| Device No. | 1 | |

| HMI No. | 0 |

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | M | M DDDD | 0~8511 | |

| Bit | SM | SM DDDD | 0~1023 | |

| Bit | S | S DDDD | 0~4095 | |

| Bit | T | T DDD | 0~511 | |

| Bit | C | C DDD | 0~255 | |

| Bit | X | X OOO | 0~571 | |

| Bit | Y | Y OOO | 0~571 | |

| Word | D | D DDDD | 0~8511 | |

| Word | SD | SD DDDD | 0~1023 | |

| Word | R | R DDDDD | 0~32767 | |

| Word | T | T DDD | 0~255 | |

| Word | C | C DDD | 0~199 | |

| Double Word | C | C DDD | 200~255 |

Cable Wiring

LS

XGB Serial

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | LS XGB CPU DRIECT | |

| Connection | RS232 | |

| Baud rate | 115200 | |

| Data bit | 8 | |

| Parity | NONE | |

| Stop bit | 1 | |

| PLC station No. | 1 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | P | P | P DDDD.f | 0~2047 | |

| Bit | M | M | M DDDD.f | 0~2047 | |

| Bit | L | L | L DDDDD.f | 0~11263 | |

| Bit | K | K | K DDDD.f | 0~2559 | |

| Bit | F | F | F DDDD.f | 0~2047 | |

| Bit | S | S | S DDDDD | 0~12799 | |

| Bit | D | D | D DDDDD.f | 0~32767 | |

| Bit | U | U | U FFFF.f | 0~7f31 | |

| Bit | T | T | T DDDD.f | 0~2047 | |

| Bit | C | C | C DDDD.f | 0~2047 | |

| Word | P | P | P DDDD | 0~2047 | |

| Word | M | M | M DDDD | 0~2047 | |

| Word | L | L | L DDDDD | 0~11263 | |

| Word | K | K | K DDDD | 0~2559 | |

| Word | F | F | F DDDD | 0~2047 | |

| Word | C | C | C DDDD | 0~2047 | |

| Word | T | T | T DDDD | 0~2047 | |

| Word | D | D | D DDDDD | 0~32767 | |

| Word | N | N | N DDDDD | 0~21503 | |

| Word | U | U | U FFFF | 0~7f31 | |

| Word | Z | Z | Z DDD | 0~127 | |

| Word | R | R | R DDDDD | 0~32767 | |

| Word | ZR | ZR | Z DDDDD | 0~32767 | |

| Word | TS | TS | TS DDDD | 0~2047 | |

| Word | CS | CS | CS DDDD | 0~2047 | |

| Word | S | S | S DDDDD | 0~12799 |

Configure the communication protocol

Pin Definition Diagram

XBC Serial

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | LS XBC CNet | |

| Connection | RS232 | |

| Baud rate | 115200 | |

| Data bit | 8 | |

| Parity | NONE | |

| Stop bit | 1 | |

| PLC station No. | 1 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | P | P | P d | 0~2047 | |

| Bit | M | M | M d | 0~2047 | |

| Bit | L | L | L d | 0~11263 | |

| Bit | K | K | K d | 0~16183 | |

| Bit | F | F | F d | 0~2047 | |

| Bit | D | D | D d | 0~32767 | |

| Bit | R | R | R d | 0~32767 | |

| Bit | U | U | U d | 0~4095 | |

| Word | P | P | P d | 0~2047 | |

| Word | M | M | M d | 0~2047 | |

| Word | L | L | L d | 0~11263 | |

| Word | K | K | K d | 0~16183 | |

| Word | F | F | F d | 0~2047 | |

| Word | C | C | C d | 0~2047 | |

| Word | T | T | T d | 0~2047 | |

| Word | D | D | D d | 0~32767 | |

| Word | N | N | N d | 0~21503 | |

| Word | R | R | R d | 0~32767 | |

| Word | U | U | U d | 0~4095 | |

| Word | Z | Z | Z d | 0~127 | |

| Word | S | S | S d | 0~127 |

Configure the communication protocol

Cable Wiring

Pin Definition Diagram

XGK FEnet(Ethernet)

Supported Series: LS XGT series XGK CPU with XGL-EFMT Ethernet module

HMI Settings

| Items | Settings | Note |

| Protocol | LG XGK FEnet(Ethernet) | |

| Connection | Ethernet | |

| Port No. | 2004 |

Address List

| Type | Register | Range | Format | Note |

| Word | P | 0~2047 | P d | |

| M | 0~2047 | M d | ||

| K | 0~2047 | K d | ||

| F | 0~2047 | F d | ||

| T | 0~2047 | T d | ||

| C | 0~2047 | C d | ||

| Z | 0~127 | Z d | ||

| S | 0~127 | S d | ||

| L | 0~11263 | L d | ||

| N | 0~21503 | N d | ||

| D | 0~32767 | D d | ||

| R | 0~32767 | R d | ||

| ZR | 0~65535 | ZR d | ||

| UxDD | 0~6331 | UxDD nndd | nn: 0~63, dd: 0~31 |

✎Note:

- In addition to the "UxDD" register, the others correspond to the PLC register one by one. UxDD corresponds to U in the PLC;

- The [UxDD] register, defined in the PLC is Ux.dd, x represents the block, and dd represents 0-31 of each block. There are 64 blocks in the PLC;

- All bit registers are in the form of bits in word, and the range is the same as the word register;

Communication settings in HMI

Enable HMI Ethernet in [Project Settings];

Set PLC IP in [Device IP] settings;

Cable Wiring

Mitsubishi

FX1S, 1N, 2N Series

Supported Series: Mitsubishi FX1S, FX1N, FX2N series

HMI Settings

| Item | Settings | Note |

| Protocol | Mitsubishi FX1S/FX1N/FX2N | |

| Connection | RS422/RS485/RS232 | |

| Baud rate | 9600~115200 | |

| Data bit | 7/8 | |

| Parity | EVEN/Odd/None | |

| Stop bit | 1/2 | |

| PLC station No. | 1~255 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

| Bit | X | X | Xo | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~99999 | ||

| S | S | S d | 0~99999 | ||

| SM | SM | SM d | 8000~9999 | ||

| Word | X | X | Xo | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~199 | ||

| D | D | D d | 0~7999 | ||

| S | S | S d | 0~99999 | ||

| SD | SD | SD d | 8000~9999 |

Cable Wiring

- RS485

- RS422

✎Note: COM3 only available in PI8000/PI9000 series.

FX3U/3G/3GA Serial

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | Mitsubishi FX3U/3G/3GA | |

| Connection | RS422 | |

| Baud rate | 9600~115200 | |

| Data bit | 7/8 | |

| Parity | EVEN/Odd/None | |

| Stop bit | 1/2 | |

| PLC station No. | 1~255 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | Xo | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~99999 | ||

| S | S | S d | 0~99999 | ||

| SM | SM | SM d | 8000~9999 | ||

| Word | X | X | Xo | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~199 | ||

| D | D | D d | 0~7999 | ||

| S | S | S d | 0~99999 | ||

| SD | SD | SD d | 8000~9999 |

Configure the communication protocol

Wiring

FX NOPROTOCOL

Mitsubishi FX3G-RS232-BD

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | Mitsubishi FX NOPROTOCOL | |

| Connection | RS232 | |

| Baud rate | 9600 | |

| Data bit | 7 | |

| Parity | EVEN | |

| Stop bit | 1 | |

| PLC station No. | 0 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | X o | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~99999 | ||

| S | S | S d | 0~99999 | ||

| SM | SM | SM d | 8000~9999 | ||

| Lamp | Lamp | Lamp d | 0~0 | ||

| Word | X | X | X o | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| T | T | T d | 0~99999 | ||

| C | C | C d | 0~199 | ||

| D | D | D d | 0~7999 | ||

| S | S | S d | 0~99999 | ||

| SD | SD | SD d | 8000~9999 |

Configure the communication protocol

Wiring

FX3U Ethernet

Mitsubishi FX3U series PLC

HMI Settings

| Items | Settings | Note |

| Protocol | Mitsubishi FX3U Ethernet | |

| Connection | Ethernet | |

| Port No. | 5009 | Must be the same as the PLC setting |

| PLC station No. | 0 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

| Bit | X | X | X OOO | 0~377 | |

| Y | Y | Y OOO | 0~377 | ||

| M | M | M DDDD | 0~7679 | ||

| SM | SM | SM DDDD | 8000~8511 | ||

| S | S | S DDDD | 0~4095 | ||

| TS | TS | TS DDD | 0~511 | ||

| CS | CS | CS DDD | 0~255 | ||

| Word | CN | CN | CN DDD | 0~199 | |

| TN | TN | TN DDD | 0~511 | ||

| D | D | D DDDD | 0~7999 | ||

| SD | SD | SD DDDD | 8000~8511 | ||

| R | R | R DDDDD | 0~32767 |

Ethernet Module Settings

FX3U-ENET-L module configuration

Set up the FX3U-ENET-L Ethernet module settings as follows.

Select the module location, which in this document is Module 0.

Select "Operational setting" to enter the following screen.

The Ethernet module IP is set to 192.168.39.254 in this document, and other options are default.

Select "Open setting" to enter the setting interface, the settings are as follows.

The third item "Protocol" selects TCP, and "Open system" selects MELSOFT connection, which allows the

Mitsubishi programming software GX works2 to communicate with the FX3U via the Ethernet module.

Click on "transter setup" - "PC side I/F setting", see the following figure.

After setting, the first download must use the programming cable, as shown in the figure; after that, can

use the IP set in the "Ethernet board" to communicate directly with the network cable.

Read and write data from the Ethernet module

Set "Transter setup" to COM communication, and read or write operation as shown below

PLC Settings (GX Works 2)

Create a blank FX5U project

Find Current Connection in the navigation

Select Connection Channel List

Select Ethernet board communication

Select Ethernet Module

Set the IP address of the PLC

Read or write PLC data, in this document is read

HMI Communication Setting

HMI Communication Setting

FX5U Serial

Mitsubishi FX5U series PLC

HMI Settings

| Item | Settings | Note |

| Protocol | Mitsubishi FX5U | |

| Connection | RS422/RS485 | |

| Baud rate | 9600 | |

| Data bit | 7 | |

| Parity | Odd | |

| Stop bit | 1 | |

| PLC station No. | 1~255 | Need to be the same as PLC settings |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

| Bit | X | X | X o | 0~303237 | |

| Y | Y | Y o | 0~303237 | ||

| M | M | M d | 0~99999 | ||

| B | B | B h | 0~7FFF | ||

| F | F | F d | 0~32767 | ||

| SB | SB | SB h | 0~7FFF | ||

| TS | TS | TS d | 0~1023 | ||

| TC | TC | TC d | 0~1023 | ||

| STS | STS | STS d | 0~1023 | ||

| STC | STC | STS d | 0~1023 | ||

| CS | CS | CS d | 0~1023 | ||

| CC | CC | CC d | 0~1023 | ||

| SM | SM | SM d | 0~9999 | ||

| L | L | L d | 0~32767 | ||

| S | S | S d | 0~4095 | ||

| Word | W | W | W h | 0~3FF | |

| TN | TN | TN d | 0~1023 | ||

| STN | STN | STN d | 0~1023 | ||

| CN | CN | CN d | 0~1023 | ||

| R | R | R d | 0~32767 | ||

| SW | SW | SW h | 0~7FFF | ||

| Z | Z | Z d | 0~23 | ||

| D | D | D d | 0~7999 | ||

| SD | SD | SD d | 0~11999 |

PLC Settings (GX Works 3)

Create a blank FX5U project

Find the 485 serial port module in the system navigation bar and double click to enter the settings.

Select protocol in the setting item, and set parameters.

Set station number, and [Message Pattern] (Pattern 1 or Pattern 4)

Click the [Apply] button to finish the setting.

Click download and select the items as below, then click [execute] to download the configuration to PLC.

As soon as download is completed, connect PLC with serial port, then configure it in the [Specify Connection Destination Connection].

Done.

Cable Wiring

- RS485

- RS422

L02 CPU Port

Mitsubishi L02 series CPU built-in serial port.

HMI Settings

| Item | Settings | Note |

|---|---|---|

| Protocol | Mitsubishi L02 CPU Port | |

| Connection | RS422 | |

| Baud rate | 115200 | |

| Data bit | 8 | |

| Parity | Odd | |

| Stop bit | 1 | |

| PLC station No. | 1~255 | Need to be the same as PLC settings |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | X | X | X h | 0~FFFF | |

| Bit | Y | Y | Y h | 0~FFFF | |

| Bit | M | M | M d | 0~9999 | |

| Bit | L | L | L d | 0~9999 | |

| Bit | F | F | F d | 0~9999 | |

| Bit | B | B | B h | 0~FFFF | |

| Bit | V | V | V d | 0~2047 | |

| Bit | TC | TC | TC d | 0~9999 | |

| Bit | SS | SS | SS d | 0~9999 | |

| Bit | SC | SC | SC d | 0~9999 | |

| Bit | CS | CS | CS d | 0~9999 | |

| Bit | CC | CC | CC d | 0~9999 | |

| Bit | SB | SB | SB h | 0~FFFF | |

| Bit | SM | SM | SM d | 0~2047 | |

| Bit | STS | STS | STS d | 0~1023 | |

| Bit | S | S | S d | 0~9999 | |

| Bit | DX | DX | DX h | 0~FFFF | |

| Bit | DY | DY | DY h | 0~FFFF | |

| Bit | TS | TS | TS d | 0~9999 | |

| Bit | Dbit | Dbit | Dbit d.d | 0~99999.0~15 | |

| Word | W | W | W h | 0~FFFF | |

| Word | TN | TN | TN d | 0~99999 | |

| Word | SN | SN | SN d | 0~99999 | |

| Word | CN | CN | CN d | 0~99999 | |

| Word | R | R | R d | 0~99999 | |

| Word | SW | SW | SW h | 0~FFFF | |

| Word | Z | Z | Z d | 0~99999 | |

| Word | ZR | ZR | ZR h | 0~FFFF | |

| Word | D | D | D d | 0~99999 |

Communication Settings

Cable Wiring

Pin Definition Diagram

L02 CPU MELSEC(Ethernet)

Mitsubishi Q series CPU built-in Ethernet port.

HMI Settings

| Items | Settings | Note |

| Protocol | MITSUBISHI L02 CPU MELSEC | |

| Connection | Ethernet | |

| Port No. | 1025 | Must be the same as the PLC setting |

| PLC station No. | 0 | Must be the same as the PLC setting |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

| Bit | X | X | X h | 0~FFFF | |

| Bit | Y | Y | Y h | 0~FFFF | |

| Bit | M | M | M d | 0~9999 | |

| Bit | L | L | L d | 0~9999 | |

| Bit | F | F | F d | 0~9999 | |

| Bit | B | B | B h | 0~FFFF | |

| Bit | V | V | V d | 0~2047 | |

| Bit | TC | TC | TC d | 0~9999 | |

| Bit | SS | SS | SS d | 0~9999 | |

| Bit | SC | SC | SC d | 0~9999 | |

| Bit | CS | CS | CS d | 0~9999 | |

| Bit | CC | CC | CC d | 0~9999 | |

| Bit | SB | SB | SB h | 0~FFFF | |

| Bit | SM | SM | SM d | 0~2047 | |

| Bit | STS | STS | STS d | 0~1023 | |

| Bit | S | S | S d | 0~9999 | |

| Bit | DX | DX | DX h | 0~FFFF | |

| Bit | DY | DY | DY h | 0~FFFF | |

| Bit | TS | TS | TS d | 0~9999 | |

| Bit | Dbit | Dbit | Dbit d.d | 0~99999.0~15 | |

| Word | W | W | W h | 0~FFFF | |

| Word | TN | TN | TN d | 0~99999 | |

| Word | SN | SN | SN d | 0~99999 | |

| Word | CN | CN | CN d | 0~99999 | |

| Word | R | R | R d | 0~99999 | |

| Word | SW | SW | SW h | 0~FFFF | |

| Word | Z | Z | Z d | 0~99999 | |

| Word | ZR | ZR | ZR h | 0~FFFF | |

| Word | D | D | D d | 0~99999 |

Communication Settings

Enable HMI Ethernet in [Project Settings];

Set PLC IP in [Device IP] settings;

PLC Settings (GX Works2 )

Create a project

Set PLC IP, subnet mask and gateway;

Select [Binary Code] as communication data code;

Set PLC port number, for example 1025

Save settings;

Download project into PLC device;

Restart PLC device;

Cable Wiring

QJ71C24N MELSEC

Mitsubishi QJ71C24N communication module built-in serial port;

HMI Settings

| Items | Settings | Note |

| Protocol | MITSUBISHI QJ71 MELSEC | |

| Connection | 422 | |

| Baud rate | 9600 | |

| Data bit | 8 | |

| Parity | ODD | |

| Stop bit | 1 | |

| PLC station No. | 1~255 | Need to be the same as PLC settings |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

| Bit | X | X | X FFFF | 0~1FFF | |

| Y | Y | Y FFFF | 0~1FFF | ||

| M | M | M DDDDD | 0~99999 | ||

| L | L | L DDDD | 0~8191 | ||

| F | F | F DDDD | 0~2047 | ||

| V | V | V DDDD | 0~2047 | ||

| B | B | B FFFF | 0~1FFF | ||

| TS | TS | TS DDDD | 0~2047 | ||

| TC | TC | TC DDDD | 0~2047 | ||

| SS | SS | SS DDDD | 0~2047 | ||

| SC | SC | SC DDDD | 0~2047 | ||

| CS | CS | CS DDDD | 0~1023 | ||

| CC | CC | CC DDDD | 0~1023 | ||

| SB | SB | SB FFF | 0~7FF | ||

| S | S | S D | 0~8191 | ||

| DX | DX | DX FFFF | 0~1FFF | ||

| DY | DY | DY FFFF | 0~1FFF | ||

| SM_ | SM_ | SM_ DDDD | 8000~9999 | ||

| SM | SM | SM DDDD | 0~2047 | ||

| Word | SD | SD | SD DDDD | 0~2047 | |

| D | D | D DDDDD | 0~12287 | ||

| W | W | W FFFF | 0~1FFF | ||

| TN | TN | TN DDDD | 0~2047 | ||

| SN | SN | SN DDDD | 0~2047 | ||

| CN | CN | CN DDDD | 0~1023 | ||

| R | R | R DDDDD | 0~32767 | ||

| SW | SW | SW FFF | 0~7FF | ||

| Z | Z | Z D | 0~15 | ||

| ZR | ZR | ZR FFFFF | 0~FE7FF |

Communication Settings

Pin Definition Diagram

QJ71E71 MELSEC

Mitsubishi QJ71E71 Ethernet communication module;

HMI Settings

| Items | Settings | Note |

| Protocol | MITSUBISHI QJ71E71 MELSEC | |

| Connection | Ethernet | |

| Port No. | 1025 | Must be the same as the PLC setting |

| PLC station No. | 0 | Must be the same as the PLC setting |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

| Bit | X | X | X h | 0~1FFF | |

| Y | Y | Y h | 0~1FFF | ||

| M | M | M d | 0~99999 | ||

| L | L | L d | 0~8191 | ||

| F | F | F d | 0~2047 | ||

| B | B | B h | 0~1FFF | ||

| V | V | V d | 0~2047 | ||

| TS | TS | TS d | 0~2047 | ||

| TC | TC | TC d | 0~2047 | ||

| SS | SS | SS d | 0~2047 | ||

| SC | SC | SC d | 0~2047 | ||

| CS | CS | CS d | 0~1023 | ||

| CC | CC | CC d | 0~1023 | ||

| SB | SB | SB h | 0~7FF | ||

| S | S | S d | 0~8191 | ||

| DX | DX | DX h | 0~1FFF | ||

| DY | DY | DY h | 0~1FFF | ||

| SM | SM | SM d | 8000~9999 | ||

| Word | SD | SD | SD d | 0~2047 | |

| D | D | D d | 0~12287 | ||

| W | W | W h | 0~1FFF | ||

| TN | TN | TN d | 0~2047 | ||

| SN | SN | SN d | 0~2047 | ||

| CN | CN | CN d | 0~1023 | ||

| R | R | R d | 0~32767 | ||

| SW | SW | SW h | 0~7FF | ||

| Z | Z | Z d | 0~15 | ||

| ZR | ZR | ZR h | 0~FE7FF |

HMI Communication Settings

1) Enable HMI Ethernet in [Project Settings];

2) Set PLC IP in [Device IP] settings

;

PLC Settings(GX Works2)

- Click [Ethernet/CC IE/MELSECNET];

- Please select [Ethernet] as network type;

- Set station I/O number according to situation (For example, 0020 means that the module is connected to PLC CPU in first order);

- Select [Online] as Mode;

- Click [Operation setting] to set IP;

- Select [Binary Code] as [Communication Data Code];

- Click [Open setting]

- Set protocol: TCP;

- Set [unpassive] in [Open system];

- Set [receive] in [Fixed buffer];

- Set [procedure Exist] in [Fixed buffer communication];

- Disable [Pairing open];

- Set [No confirm] in [Existence confirmation];

- Host station port number: 5009;

Save settings;

Save settings;

- Download project into PLC and restart it

Cable Wiring

MODBUS

MODBUS RTU Master

Supported Series: MODBUS RTU CONTROLLER

HMI works as MODBUS SLAVE connecting with MASTER

HMI Settings

| Items | Settings | Note |

| Protocol | MODBUS RTU Master | |

| Connection | RS485/RS232 | |

| Baud rate | 2400~187500 | |

| Data bit | 8 | |

| Parity | Even/ Odd/ None | |

| Stop bit | 1/2 | |

| Station No. | 0~255 |

Address List

| Type | HMI address | MODBUS code | Range |

| Bit | HDX3000.0~HDX3499.15 | 0 | 0~7999 |

| Word | HDW3500~HDW7999 | 4 | 0~4499 |

Cable Wiring

- RS485

- RS232

✎Note: COM3 only available in PI8000/PI9000 series.

MODBUS RTU Slave (All function)/(All function OneBaseAddress)

Supported Series: MODBUS RTU CONTROLLER

HMI works as MODBUS MASTER connecting with SLAVE.

The addresses in [All function] start from 0, while the addresses in [All function OneBaseAddress] start from 1 (offset 1).

HMI Settings

| Items | Settings | Note |

| Protocol | MODBUS RTU Slave (All function)/( All function OneBaseAddress) | |

| Connection | RS485/RS232 | |

| Baud rate | 2400~187500 | |

| Data bit | 8 | |

| Parity | Even/ Odd/ None | |

| Stop bit | 1/2 | |

| PLC station No. | 0~255 |

Address List

| Type | Address Type | Function code & Description |

| Word | 3 | 04 (read input register: read current binary value in one or more input registers) |

| 06 (write single register: write a binary value to a holding register) | ||

| 10 (write values to multiple addresses ) | ||

| 4 | 03 (read holding register: read current binary value in one or more holding registers) | |

| 06 (write single register: write a binary value to a holding register) | ||

| 10 (write values to multiple addresses ) | ||

| W6 | 03 (read holding register: read current binary value in one or more holding registers) | |

| 06 (write single register: write a binary value to a holding register) | ||

| 10 (write values to multiple addresses ) | ||

| W16 | 03 (read holding register: read current binary value in one or more holding registers) | |

| 10 (write values to multiple addresses ) | ||

| Bit | 0 | 01 (Read coil state) |

| 05 (Force a single coil to force the on/off state of a logic coil) | ||

| 0F (Write multiple bits, ie write continuously) | ||

| 1 | 02 (Read the input state) | |

| 05 (Force a single coil to force the on/off state of a logic coil) | ||

| 0F (Write multiple bits) | ||

| W5 | 01 (Read coil state to obtain the current state of a set of logic coils) | |

| 05 (Force a single coil to force the on/off state of a logic coil) | ||

| 0F (Write multiple bits) | ||

| W15 | 01 (Read coil state to obtain the current state of a set of logic coils) | |

| 0F (Write multiple bits) |

✎Note:

- Modbus can also support getting bit from the word, which could access the address such as 100.1 and other formats.

- The function codes sent out are the same as those that read and write words.

Station number for more than one slaves

If there are more than one slaves connected to HMI, please set slave station number during editing address, as below shows.

Cable Wiring

- RS485

- RS232

✎Note: COM3 only available in PI8000/PI9000 series.

Modbus Meter

The following example is using the Linfee meter LNF96EY to demonstrate how to set up the Modbus communication.

1. Wiring the RS485 cable first. Because the pin 58 is A, the pin 59 is B for meter. Here we use the COM1 to connect. So the diagram like follows:

2. Check the specific Modbus parameter in the communication menu from LED display.

So from the following pictures, we can know the Meter Address is 85, Baud rate is 9600, CRC None.

3. Create new project and change the Communication settings.

Set the protocol as MODBUS RTU Slave (All Function), set Device No. as 85. And COM port setting as 9600, 1, 8, NONE.

4. Drag the numeric input into screen, and fill in the Modbus Address we want to read according to manual

The following table is intercept part of the manual for Linfee Modbus manual.

0x03/0x04 command data register address:

| Address | Description | Data Format | Data Length(Word) | Remark | |

|---|---|---|---|---|---|

| HEX | DEC | ||||

| 0x00 | 0 | Reserved | |||

| 0x02 | 2 | Reserved | |||

| 0x04 | 4 | Reserved | |||

| 0x06 | 6 | Ua | float | 2 | Phase Voltage data, Unit V |

| 0x08 | 8 | Ub | float | 2 | Phase Voltage data, Unit V |

| 0x0A | 10 | Uc | float | 2 | Phase Voltage data, Unit V |

| 0x0C | 12 | Uab | float | 2 | Line Voltage data, Unit V |

| 0x0E | 14 | Ubc | float | 2 | Line Voltage data, Unit V |

| 0x10 | 16 | Uca | float | 2 | Line Voltage data, Unit V |

| 0x12 | 18 | Ia | float | 2 | Phase Current data, Unit A |

| 0x14 | 20 | Ib | float | 2 | Phase Current data, Unit A |

| 0x16 | 22 | Ic | float | 2 | Phase Current data, Unit A |

For example, here we want to read the Phase Voltage Ua (Modbus offset 0006), the Address No. requires input decimal number, and check whether the actual address has one address offset, so the address set like the following screenshot:

Set the Read-Write type for address, because meter only to measuring the data, so set it as read-only, and floating data format.

Then download into HMI, if the HMI COM led is blinking and no timeout message show, which means the communication is setup successfully.

MODBUS TCP Slave (All function)

Supported series: MODBUS TCP controller

Note: Although the protocol selected for the HMI is MODBUS TCP Slave, the HMI is working as a MODBUS TCP Master connected to TCP SLAVE.

HMI Setting

| Items | Settings | Note |

| Protocol | MODBUS TCP Slave (All function) | |

| Connection | Ethernet | |

| Port No. | 502 | |

| PLC station No. | 1 |

Address List

| Type | Register | Function code & Description |

| Word | 3 | 04 (read input register: read current binary value in one or more input registers) |

| 06 (write single register: write a binary value to a holding register) | ||

| 10 (write values to multiple addresses ) | ||

| 4 | 03 (read holding register: read current binary value in one or more holding registers) | |

| 06 (write single register: write a binary value to a holding register) | ||

| 10 (write values to multiple addresses ) | ||

| W6 | 03 (read holding register: read current binary value in one or more holding registers) | |

| 06 (write single register: write a binary value to a holding register) | ||

| 10 (write values to multiple addresses ) | ||

| W16 | 03 (read holding register: read current binary value in one or more holding registers) | |

| 10 (write values to multiple addresses ) | ||

| Bit | 0 | 01 (Read coil state) |

| 05 (Force a single coil to force the on/off state of a logic coil) | ||

| 0F (Write multiple bits, ie write continuously) | ||

| 1 | 02 (Read the input state) | |

| 05 (Force a single coil to force the on/off state of a logic coil) | ||

| 0F (Write multiple bits) | ||

| W5 | 01 (Read coil state to obtain the current state of a set of logic coils) | |

| 05 (Force a single coil to force the on/off state of a logic coil) | ||

| 0F (Write multiple bits) | ||

| W15 | 01 (Read coil state to obtain the current state of a set of logic coils) | |

| 0F (Write multiple bits) |

Communication Settings

Enable HMI Ethernet in [Project Settings];

Set PLC IP in [Device IP] settings;

Cable Wiring

Omron

CJ TCP FINS Ethemet

Supported device:CJ series, CJ1W-EIP21

HMI Settings

| Items | Settings | Note |

|---|---|---|

| Protocol | OMRON CJ TCP FINS Ethemet | |

| Connection | Ethernet | |

| Port No. | 9600 | |

| Device No. | 0 | |

| HMI No. | 0 |

|

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | CIO | CIO | CIO d | 0~99999 | |

| Bit | W | W | W d | 0~99999 | |

| Bit | D | D | D d | 0~99999 | |

| Bit | H | H | H d | 0~99999 | |

| Bit | A | A | A d | 0~99999 | |

| Bit | T | T | T h | 0~99999 | |

| Bit | CF | CF | CF d | 0~99999 | |

| Bit | FF | FF | FF d | 0~99999 | |

| Bit | C | C | C d | 0~99999 | |

| Bit | EM0 | EM0 | EM0 d | 0~99999 | |

| Bit | EM1 | EM1 | EM1 d | 0~99999 | |

| Bit | EM2 | EM2 | EM2 d | 0~99999 | |

| Bit | EM3 | EM3 | EM3 d | 0~99999 | |

| Bit | EM4 | EM4 | EM4 d | 0~99999 | |

| Bit | EM5 | EM5 | EM5 h | 0~99999 | |

| Bit | EM6 | EM6 | EM6 d | 0~99999 | |

| Bit | EM7 | EM7 | EM7 d | 0~99999 | |

| Bit | EM8 | EM8 | EM8 d | 0~99999 | |

| Bit | EM9 | EM9 | EM9 d | 0~99999 | |

| Bit | EMA | EMA | EMA d | 0~99999 | |

| Bit | EMB | EMB | EMB d | 0~99999 | |

| Bit | EMC | EMC | EMC d | 0~99999 | |

| Bit | Lamp | Lamp | Lamp d | 0~0 | |

| Word | CIO | CIO | CIO d | 0~99999 | |

| Word | W | W | W d | 0~99999 | |

| Word | D | D | D d | 0~99999 | |

| Word | H | H | H d | 0~99999 | |

| Word | A | A | A d | 0~99999 | |

| Word | T | T | T h | 0~99999 | |

| Word | CF | CF | CF d | 0~99999 | |

| Word | FF | FF | FF d | 0~99999 | |

| Word | C | C | C d | 0~99999 | |

| Word | EM0 | EM0 | EM0 d | 0~99999 | |

| Word | EM1 | EM1 | EM1 d | 0~99999 | |

| Word | EM2 | EM2 | EM2 d | 0~99999 | |

| Word | EM3 | EM3 | EM3 d | 0~99999 | |

| Word | EM4 | EM4 | EM4 d | 0~99999 | |

| Word | EM5 | EM5 | EM5 h | 0~99999 | |

| Word | EM6 | EM6 | EM6 d | 0~99999 | |

| Word | EM7 | EM7 | EM7 d | 0~99999 | |

| Word | EM8 | EM8 | EM8 d | 0~99999 | |

| Word | EM9 | EM9 | EM9 d | 0~99999 | |

| Word | EMA | EMA | EMA d | 0~99999 | |

| Word | EMB | EMB | EMB d | 0~99999 | |

| Word | EMC | EMC | EMC d | 0~99999 | |

| Word | IR | IR | IR d | 0~99999 | |

| Word | DR | DR | DR d | 0~99999 |

Configure the communication protocol

Configure CJ1W-EIP21 connect with HMI

Select TCP_Client_2N

Cable Wiring

Pin Definition Diagram

CS1(CP1E/CP1H)

Supported device: OMRON CS1(CP1E/CP1H)

HMI Settings

| Items | Settings | Note |

|---|---|---|

| Protocol | OMRON CS1(CP1E/CP1H) | |

| Connection | RS232 (9600, 2, 7, EVEN) | |

| Port No. | None | |

| PLC station No. | 0 |

Address List

| Type | Device registers | HMI registers | Format | Range | Note |

|---|---|---|---|---|---|

| Bit | CIO | CIO | CIO d | 0~99999 | |

| Bit | W | W | W d | 0~99999 | |

| Bit | D | D | D d | 0~99999 | |

| Bit | H | H | H d | 0~99999 | |

| Bit | A | A | A d | 0~99999 | |

| Bit | TF | T | T h | 0~99999 | |

| Bit | CF | CF | CF d | 0~99999 | |

| Bit | T | FF | FF d | 0~99999 | |

| Bit | C | C | C d | 0~99999 | |

| Bit | EM0 | EM0 | EM0 d | 0~99999 | |

| Bit | EM1 | EM1 | EM1 d | 0~99999 | |

| Bit | EM2 | EM2 | EM2 d | 0~99999 | |

| Bit | EM3 | EM3 | EM3 d | 0~99999 | |

| Bit | EM4 | EM4 | EM4 d | 0~99999 | |

| Bit | EM5 | EM5 | EM5 h | 0~99999 | |

| Bit | EM6 | EM6 | EM6 d | 0~99999 | |

| Bit | EM7 | EM7 | EM7 d | 0~99999 | |

| Bit | EM8 | EM8 | EM8 d | 0~99999 | |

| Bit | EM9 | EM9 | EM9 d | 0~99999 | |

| Bit | EMA | EMA | EMA d | 0~99999 | |

| Bit | EMB | EMB | EMB d | 0~99999 | |

| Bit | EMC | EMC | EMC d | 0~99999 | |

| Word | CIO | CIO | CIO d | 0~99999 | |

| Word | W | W | W d | 0~99999 | |

| Word | D | D | D d | 0~99999 | |

| Word | H | H | H d | 0~99999 | |

| Word | A | A | A d | 0~99999 | |

| Word | T | T | T h | 0~99999 | |

| Word | CIO | CF | CF d | 0~99999 | |

| Word | C | C | C d | 0~99999 | |

| Word | EM0 | EM0 | EM0 d | 0~99999 | |

| Word | EM1 | EM1 | EM1 d | 0~99999 | |

| Word | EM2 | EM2 | EM2 d | 0~99999 | |

| Word | EM3 | EM3 | EM3 d | 0~99999 | |

| Word | EM4 | EM4 | EM4 d | 0~99999 | |

| Word | EM5 | EM5 | EM5 h | 0~99999 | |

| Word | EM6 | EM6 | EM6 d | 0~99999 | |

| Word | EM7 | EM7 | EM7 d | 0~99999 | |

| Word | EM8 | EM8 | EM8 d | 0~99999 | |

| Word | EM9 | EM9 | EM9 d | 0~99999 | |

| Word | EMA | EMA | EMA d | 0~99999 | |

| Word | EMB | EMB | EMB d | 0~99999 | |

| Word | EMC | EMC | EMC d | 0~99999 | |

| Word | IR | IR | IR d | 0~99999 | |

| Word | DR | DR | DR d | 0~99999 |

Configure the communication protocol

PLC Settings(CX-Programmer)

Open cx-programmer, create a new PLC project or open the project that has been created.

Create new project: [File]→[New]→[Device Type]CP1E→[settings]→[General]→[CPU Type]N30→[OK]→[OK].

PLC Default Parameters:[Settings]→[Built-in RS232C Port]→[Communication Settings]→[Standard]9600,1,7,2,E means:[Baud rate] 9600, [Data bits]7, [Stop bits] 2,[Parity] EVEN→[Unit Number]0 →[Mode]Host Link(Defaut).

Cable Wiring

Pin Definition Diagram

EC55 Protocol

Supported device: EC55 temperature instrument

1)HMI Settings

| Items | Settings | Note |

| Protocol | Omron EC55 | |

| Connection | RS485 (9600, 2, 7, EVEN) | |

| Port No. | None | |

| PLC station No. | 0 |

2)Address List

| Type | Register | Device range | HMI range | Function |

| Double word | C0 | 0-13 (Hex) | 0-19 | Set read only parameter for area 0 |

| C1 | 0-4D(Hex) | 0-77 | Set Read/Write parameter for area 0 | |

| C3 | 0-CD(Hex) | 0-205 | Set Read/Write parameter for area 1 | |

| Word | 80 | 0-13(Hex) | 0-19 | Set read only parameter in area 0 |

| 81 | 0-4D(Hex) | 0-77 | Set Read/Write parameter in area 0 | |

| 83 | 0-CD(Hex) | 0-205 | Set Read/Write parameter in area 1 | |

| CP | - | 0-6 | Read controller intrinsic property | |

| CS | - | 0-2 | Read controller states | |

| CA | - | 0-17 | Action command |

3)Device Settings

Omron E5CC PLC configuration

After entering the Communication Settings menu, please set the parameters to the default values for the following table. Press the cycle key of the instrument to enter the next setting.

According to PLC configuration and communication port configuration information of the HMI, provide the corresponding steps and configuration screenshots. This configuration needs to communicate properly with the above PLC configuration. The project settings are as follows

✎Note: The communication settings for HMI should be consistent with this setting.

Cable Wiring

✎Note:

- COM3 only available in PI8000/PI9000 series.

- CA address could not support continuous writing function;

- Because of CP address intrinsic property: read control intrinsic property, so please place the character input part in use. Set address with CP0 and character length 10, used to display controller type. And place a number input part, set address with CP5 (cache size). Do not place other CP type address without CP0 in screen, otherwise CP type address is invalid

- When set value into read & write address, it is necessary to switch the temperature instrument meter to the corresponding interface according to the menu of the instrument where the address locates, so that the value could be written, otherwise, the value could not be written; When the communication write setting of the instrument is turned off, the writing function is invalid. Writing function could be opened by using the 00 address of the CA register, which write 01 value.

- When continuous writing of a value to a read-write address, please make sure all continuous writing address could be written. Otherwise, if one of these addresses could not be written, then all continuous writing commands will fail.

- Because of the mechanism problem, this protocol could not support CompoWay/F function that is read-write function of variables in protocol document.

- When using double-word address, set the data format to 32 bits, otherwise the read/write function is unable.

- Please set the communication delay time of 10ms in setting, to avoid that the instrument may not be able to communicate in a short time due to too fast data access and too much connection requests.

Because of the particularity of the instrument, it is necessary to write the value of the address in the menu interface corresponding to the address, and to enter the menu where the address locates, so that the value could be written.

Because of the particularity of the instrument, it is necessary to write the value of the address in the menu interface corresponding to the address, and to enter the menu where the address locates, so that the value could be written.

NX EtherNet/IP

Supported series: Omron NX/NJ series

HMI Setting

| Items | Settings | Note |

| Protocol | Omron NX Ethernet/IP | |

| Connection | Ethernet | |

| Port No. | 44818 | |

| PLC station No. | 1 |

Instruction

1) In Sysmac Studio, please select [Publish Only] for [Network Publish] when setting address tag.

2) When [Do not publish] is selected for a tag, different import methods may lead to different results. When import tags by [Get Tags from Device], the tag will be eliminated. If [Import tags] is selected, the tags will be imported, but the communication will not succeed.

Export labels from Sysmac Studio

Launch Sysmac Studio, under Global Variables create the address labels, and thenselect [Tools] -> [Export Global Variables];

Launch PIStudio, in [Communication] Settings add Omron NX Ethernet/IP protocol;

Click [Label manage];

Click [Import labels] and then select the file exported in step 1;

The Import Status field shows the result, click [OK] to finish importing address labels;

Communication Settings

Enable HMI Ethernet in [Project Settings];

Set PLC IP in [Device IP] settings;

Cable Wiring

CV/CJ1M/CS1H

HMI Setting:

| Parameters | Recommended |

|---|---|

| PLC type | OMRON CV/CJ1M/CS1H |

| PLC I/F | RS232/RS485 |

| Baud rate | 9600 |

| Data bits | 7 |

| Parity | Even |

| Stop bits | 2 |

| PLC sta. no. | 0 |

PLC Setting:

Open cx-programmer, create a new PLC project or open the project that has been created.

Create new project: [File]→[New]→[Device Type]CJ2M→[settings]→[General]→[CPU Type]CPU31→[OK]→[OK].

PLC Default Parameters:[Settings]→[Serial Port]→[Communication Settings]→[Standard]9600,1,7,2,E means:[Baud rate] 9600, [Data bits]7, [Stop bits] 2,[Parity] EVEN→[Unit Number]0 →[Mode]Host Link.

Note:The serial port parameters should be set depending on field requirements

Device Address:

| Bit/Word | Device type | Format | Range | Memo |

|---|---|---|---|---|

| B | CIO | DDDDDdd | 0 ~65535.15 | I/O and Internal Relay |

| B | W | DDDDDdd | 0 ~65535.15 | Hold Relay |

| B | D | DDDDDdd | 0 ~65535.15 | Link Relay |

| B | H | DDDDDdd | 0 ~65535.15 | |

| B | A | DDDDDdd | 0 ~65535.15 | |

| B | TF | DDDDD | 0 ~ 99999 | |

| B | CF | DDDDD | 0 ~ 99999 | Auxiliary Relay |

| B | T | DDDDDdd | 0 ~65535.15 | |

| B | C | DDDDDdd | 0 ~65535.15 | |

| B | EM0 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM1 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM2 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM3 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM4 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM5 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM6 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM7 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM8 | DDDDDdd | 0 ~ 99999.15 | |

| B | EM9 | DDDDDdd | 0 ~ 99999.15 | |

| B | EMA | DDDDDdd | 0 ~ 99999.15 | |

| B | EMB | DDDDDdd | 0 ~ 99999.15 | |

| B | EMC | DDDDDdd | 0 ~ 99999.15 | |

| B | Lamp | D | 0~0 |

| Bit/Word | Device type | Format | Range |

|---|---|---|---|

| W | W | DDDDD | 0 ~ 99999 |

| W | D | DDDDD | 0 ~ 99999 |

| W | H | DDDDD | 0 ~ 99999 |

| W | A | DDDDD | 0 ~ 99999 |

| W | T | DDDDD | 0 ~ 99999 |

| W | C | DDDDD | 0 ~ 99999 |

| W | CIO | DDDDD | 0 ~ 99999 |

| W | EM0 | DDDDD | 0 ~ 99999 |

| W | EM1 | DDDDD | 0 ~ 99999 |

| W | EM2 | DDDDD | 0 ~ 99999 |

| W | EM3 | DDDDD | 0 ~ 99999 |

| W | EM4 | DDDDD | 0 ~ 99999 |

| W | EM5 | DDDDD | 0 ~ 99999 |

| W | EM6 | DDDDD | 0 ~ 99999 |

| W | EM7 | DDDDD | 0 ~ 99999 |

| W | EM8 | DDDDD | 0 ~ 99999 |

| W | EM9 | DDDDD | 0 ~ 99999 |

| W | EMA | DDDDD | 0 ~ 99999 |

| W | EMB | DDDDD | 0 ~ 99999 |

| W | EMC | DDDDD | 0 ~ 99999 |

| W | IR | DDDDD | 0 ~ 99999 |

| W | DR | DDDDD | 0 ~ 99999 |

Wiring Diagram:

RS-485

Pin Definition Diagram

RS-232

CPU Port (CPM2A,CQM1/1H,C200H/HS/ALPHA series)

Communication Module:

CPM1-CIF01 adapter (for CPM1/CPM1A/CPM2A series, CQM1/CQM1H series) CPM1H-SCB41 communication module (for CQM1H-CPU51/61)

The serial port pin assignments may vary between HMI models, please click the following link for more information.

OMRON HOSTLINK

Supported series: Omron C200HE series

HMI Settings(recommended)

| Item | Recommended |

|---|---|

| Protocol | OMRON HOSTLINK |

| Connection | RS232 |

| Baud rate | 9600 |

| Stop bits | 2 |

| Data bits | 7 |

| Parity | EVEN |

| PLC Station No. | 0 |

| HMI Station No. | 0 |

Address List

| Type | Device registers | HMI registers | Format | Range |

|---|---|---|---|---|

| Bit | IR | IR | IR d | 0~99999 |

| Bit | LR | LR | LR d | 0~99999 |

| Bit | HR | HR | HR d | 0~99999 |

| Bit | AR | AR | AR d | 0~99999 |

| Bit | TIMB | TIMB | TIMB d | 0~99999 |

| Bit | CNTB | CNTB | CNTB d | 0~99999 |

| Bit | TIM | TIM | TIM d | 0~99999 |

| Bit | DM | DM | DM d | 0~99999 |

| Bit | CNT | CNT | CNT d | 0~99999 |

| Bit | WR | WR | WR d | 0~99999 |

| Bit | LAMP | LAMP | LAMP d | 0~0 |

| Word | IR | IR | IR d | 0~99999 |

| Word | LR | LR | LR d | 0~99999 |

| Word | HR | HR | HR d | 0~99999 |

| Word | AR | AR | AR d | 0~99999 |

| Word | TIM | TIM | TIM d | 0~99999 |

| Word | DM | DM | DM d | 0~99999 |

| Word | CNT | CNT | CNT d | 0~99999 |

| Word | WR | WR | WR d | 0~99999 |

Cable Wiring

Rockwell

DF1

MicroLogix 1000/1100/1200/1400/1500; SLC 5/03 5/04 5/05; PLC-5

HMI Settings

| Item | Recommended | Note |

|---|---|---|

| Protocol | Rockwell DF1 | |

| Connection | RS232 | |

| Baud rate | 19200 | |

| Stop bits | 1 | |

| Data bits | 8 | |

| Parity | None | |

| PLC Station No. | 1 | |

| HMI Station No. | 0 |

PLC Settings

DF1 Full Duplex protocol and CRC error check

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | I | I ddd.dd | 0.0~255.15 | Only able to communicate with file number I1 |

| O | O ddd.dd | 0.0~255.15 | Only able to communicate with file number O0 | |

| B | B nnhh.dd | 0.0~ffff.15 | Only able to communicate with file number B3 | |

| S | S ddd.dd | 0.0~255.15 | Only able to communicate with file number S2 | |

| N | N nnhh.dd | 0.0~ffff.15 | Only able to communicate with file number N7 | |

| Word | S | S ddd | 0~255 | Only able to communicate with file number S2 |

| TS | TS nnhh | 0~ffff | Only able to communicate with file number T4 (Timer Preset Value) | |

| TP | TP nnhh | 0~ffff | Only able to communicate with file number T4 (Timer Accumulator Value) | |

| CS | CS nnhh | 0~ffff | Only able to communicate with file number C5 (Counter Preset Value) | |

| CP | CP nnhh | 0~ffff | Only able to communicate with file number C5 (Counter Accumulator Value) | |

| N | N nnhh | 0~ffff | Only able to communicate with file number N7 |

Cable Wiring

DF1 Advanced

MicroLogix 1000/1100/1200/1400/1500; SLC 5/03 5/04 5/05; PLC-5

HMI Settings

| Item | Recommended | Note |

|---|---|---|

| Protocol | Rockwell DF1 Advanced | |

| Connection | RS232 | |

| Baud rate | 19200 | |

| Stop bits | 1 | |

| Data bits | 8 | |

| Parity | None | |

| PLC Station No. | 1 | |

| HMI Station No. | 0 |

PLC Settings

DF1 Full Duplex protocol and CRC error check

Address List

| Type | Device registers | Format | Range | Note |

|---|---|---|---|---|

| Bit | I1 | I1ddd.dd | 0.0~255.15 | Only able to communicate with file number I1 |

| O0 | O0ddd.dd | 0.0~255.15 | Only able to communicate with file number O0 | |

| S2 | S2ddd.dd | 0.0~255.15 | Only able to communicate with file number S2 | |

| B3 | B3ddd.dd | 0.0~255.15 | Only able to communicate with file number B3 | |

| BN | BNddddd.dd | 0.0~99255.15 | Bit data file B0~B99 First two digits is for file number For example, BN13001.00 represents file number B13, address 001, the 0th bit. | |

| N7 | N7ddd.dd | 0.0~255.15 | Only able to communicate with file number N7 | |

| NN | NNddddd.dd | 0.0~99255.15 | Integer data file bit format N0~N99 First two digits is for file number For example, NN13001.00 represents file number N13, address 001, the 0th bit. | |

| Word | S2 | S2ddd | 0~255 | Only able to communicate with file number S2 |

| T4S | T4Sddd | 0~255 | Only able to communicate with file number T4 (Timer Preset Value) | |

| T4P | T4Pddd | 0~255 | Only able to communicate with file number T4 (Timer Accumulator Value) | |

| TNS | TNSddddd | 0~99255 | Timer Preset Value First two digits is for file number For example, TNS99255 represents file number T99, address 255. | |

| TNP | TNPddddd | 0~99255 | Timer Accumulator Value First two digits is for file number For example, TNP99255 represents file number T99, address 255. | |

| C5S | C5Sddd | 0~255 | Only able to communicate with file number C5 (Counter Preset Value) | |

| C5P | C5Pddd | 0~255 | Only able to communicate with file number C5 (Counter Accumulator Value) | |

| CNS | CNSddddd | 0~99255 | Counter Preset Value First two digits is for file number For example, CNS99255 represents file number C99, address 255. | |

| CNP | CNPddddd | 0~99255 | Counter Accumulator Value First two digits is for file number For example, CNP99255 represents file number C99, address 255. | |

| N7 | N7ddd | 0~255 | Only able to communicate with file number N7 | |

| NN | NNddd | 0~99255 | Integer data file First two digits is for file number For example, NN99255 represents file number N99, address 255. | |

| Double Word | F8 | F8ddd | 0~255 | Only able to communicate with file number F8 |

| FN | FNddddd | 0~99255 | Floating point data file First two digits is for file number For example, FN99255 represents file number F99, address 255. | |

| LN | LNddddd | 0~99255 | Long |

Cable Wiring

MicroLogix

MicroLogix 1000/1100/1200/1400/1500; SLC 5/03 5/04 5/05 PLC-5

HMI Settings

| Item | Settings | Note |

| Protocol | Allen-Bradlley MicroLogix | |

| Connection | RS232 | |

| Baud rate | 19200 | |

| Data bit | 8 | |

| Parity | None | |

| Stop bit | 1 | |

| PLC station No. | 1 |

Address List

| Type | Device registers | Format | Range | Note |

| Bit | I | I d.d | 0.0~255.15 | |

| O | O d.d | 0.0~255.15 | ||

| B | B nnhh.dd | 0.0~ffff.15 | nn: block number (hex) | |

| S | S d.d | 0.0~255.15 | ||

| N | N nnhh.dd | 0.0~ffff.15 | nn: block number (hex) | |

| Word | S | S d | 0~255 | |

| TS | TS nnhh | 0~ffff | nn: block number (hex) | |

| TP | TP nnhh | 0~ffff | ||

| CS | CS nnhh | 0~ffff | ||

| CP | CP nnhh | 0~ffff | ||

| N | N nnhh | 0~ffff | ||

| C | C nnhh | 0~ffff | ||

| T | T nnhh | 0~ffff | ||

| R | R nnhh | 0~ffff |

Cable Wiring

EtherNet/IP(CompactLogix Series)

Allen-Brandly Compact Logix Free Tag

HMI Settings

| Items | Settings | Note |

| Protocol | EtherNet/IP(CompactLogix Series) | |

| Connection | Ethernet | |

| Port No. | 44818 |

PLC Setting

Create new tags

Export tags to CSV file. ([Tools] » [Export] » [Tags and Logic Comments])

Import labels, please open [Communication] window and click [Import label];

Select csv file, all tags will be displayed as belows;

✎Note:

Because in different region, the separation symbol is different, we suggest you check this before you want to import your tags. To open csv file as text format.

The directory of changing system settings: [Control Panel] -> [Date, Time, Language,and Regional Options] -> [Change the format of numbers, dates, and times]->[Customize]-> [List separator]. Please select [,] and export CSV file after setting.

Communication settings in HMI

Enable HMI Ethernet in [Project Settings];

Set PLC IP in [Device IP] settings;

Cable Wiring

MicroLogix 1200

The operational address is determined by the connection of Allen-Bradley PLC to HMI. For extension modules or other special conditions, refer to allen-Bradley PLC instruction manual. The following is an example of allen-bradley MicroLogix1200.

- Bit address I: The address ranges from 0.0 to 255.15. The value of the data before the decimal point ranges from 0 to 255 (decimal). The value from 0 to 15 after the decimal point is the sub address (decimal).

- Bit address B: The address ranges from 000.0 to fff.15. The first f from left to right represents the block number (hexadecimal); The second and third f from left to right represent the word address (hexadecimal). The value 0 to 15 after the decimal point reprensents the sub address (decimal).

- Word address S: The word address ranges from 0 to 255 (decimal).

- Word address TS: The address ranges from 000.0 to ffff. The first and second f from left to right represents the block number (hexadecimal); The third and fourth f from left to right represent the word address (hexadecimal).

✎Note: Register address TP, CS, CP, N, F and TS address edit are same. D indicates decimal, and F indicates hexadecimal. Different PLC models may support different registers. See the following table.

| PLC bit address type | Address format | Address range |

| I | dd.dd | I 0.0 ~ 255.15 |

| O | dd.dd | O 0.0 ~ 255.15 |

| B | fff.dd | B 000.0 ~ fff.15 |

| S | dd.dd | S 0.0 ~ 255.15 |

| N | ffff.dd | N 000.0 ~ fff.15 |

| PLC word address type | Address format | Address range |

| S | ddd | S0 ~ 255 |

| TS | ffff | TS0 ~ FFFF |

| TP | ffff | TP0 ~ FFFF |

| CS | ffff | CS0 ~ FFFF |

| CP | ffff | CP0 ~ FFFF |

| N | ffff | N0 ~ FFFF |

| F | ffff | F0 ~ FFFF |

Siemens

S7-200 Smart Ethernet

Supported Series: Siemens S7-200 SMART Series Ethernet Module.

Website: http://www.siemens.com/entry/cc/en/

HMI Setting

| Items | Settings | Note |

| Protocol | Simens S7-200 Smart Ethernet | |

| Connection | Ethernet | |

| Port No. | 102 | |

| PLC station No. | 2 |

Address List

| Type | Device register | HMI register | Format | Range | Note |

| Bit | I | I | I ddddd.o | 0.0~99999.7 | |

| Q | Q | Q ddddd.o | 0.0~99999.7 | ||

| V | VWbit | VWbit ddddd.o | 0.0~99999.7 | ||